Industries

Review the RazorGage Product line according to Industry Applications.

Cabinets

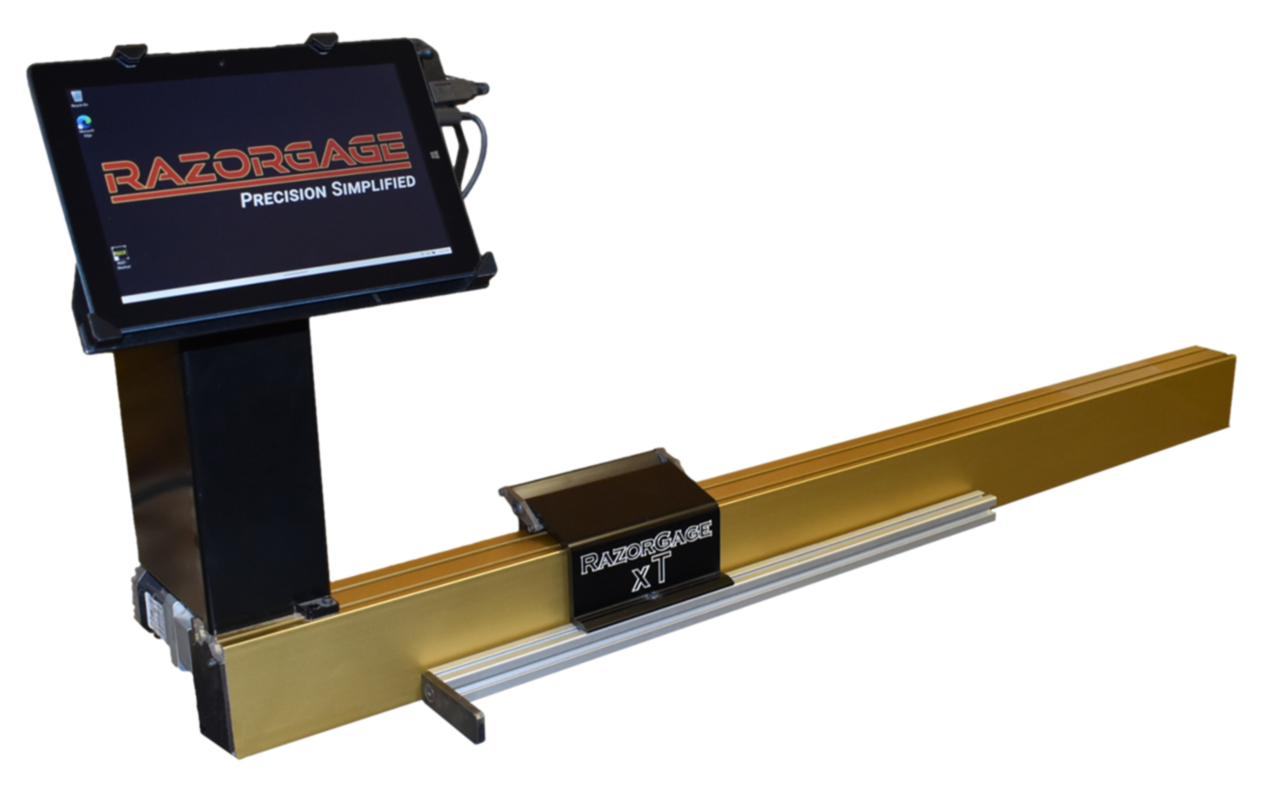

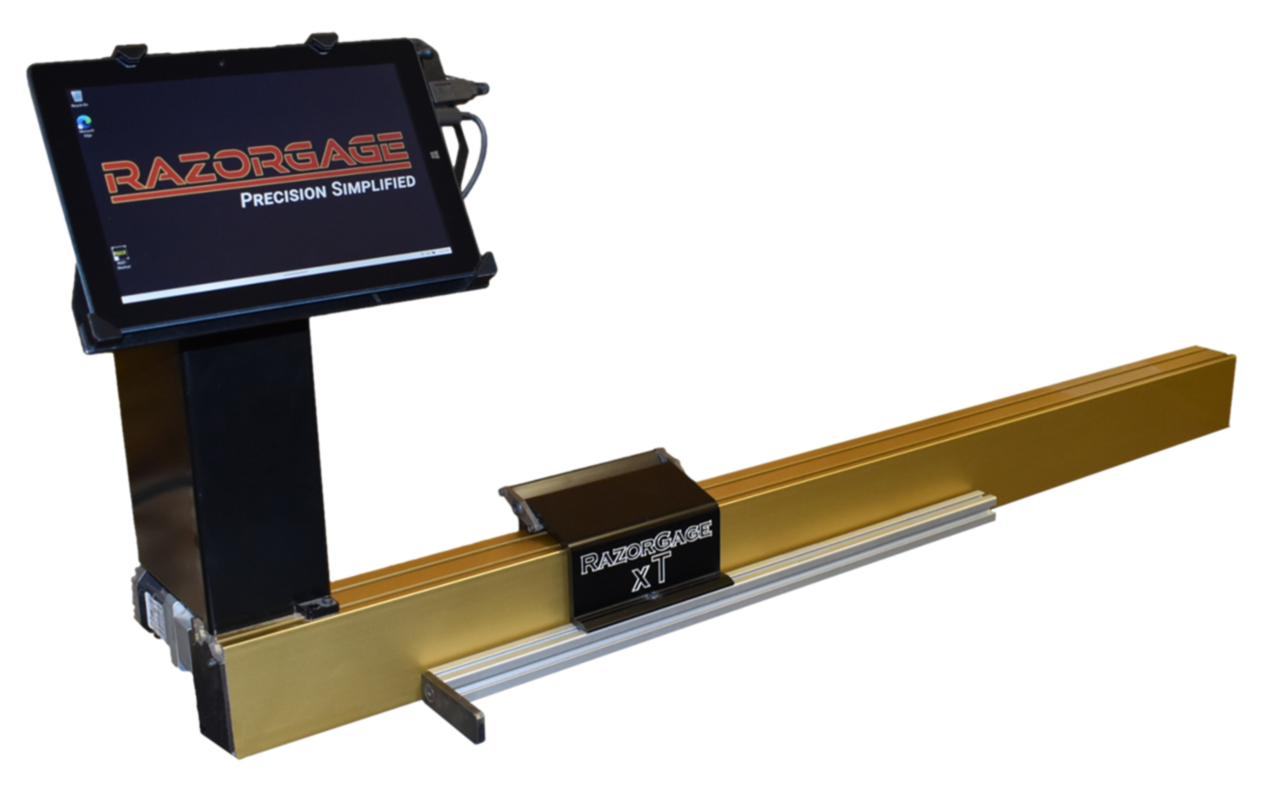

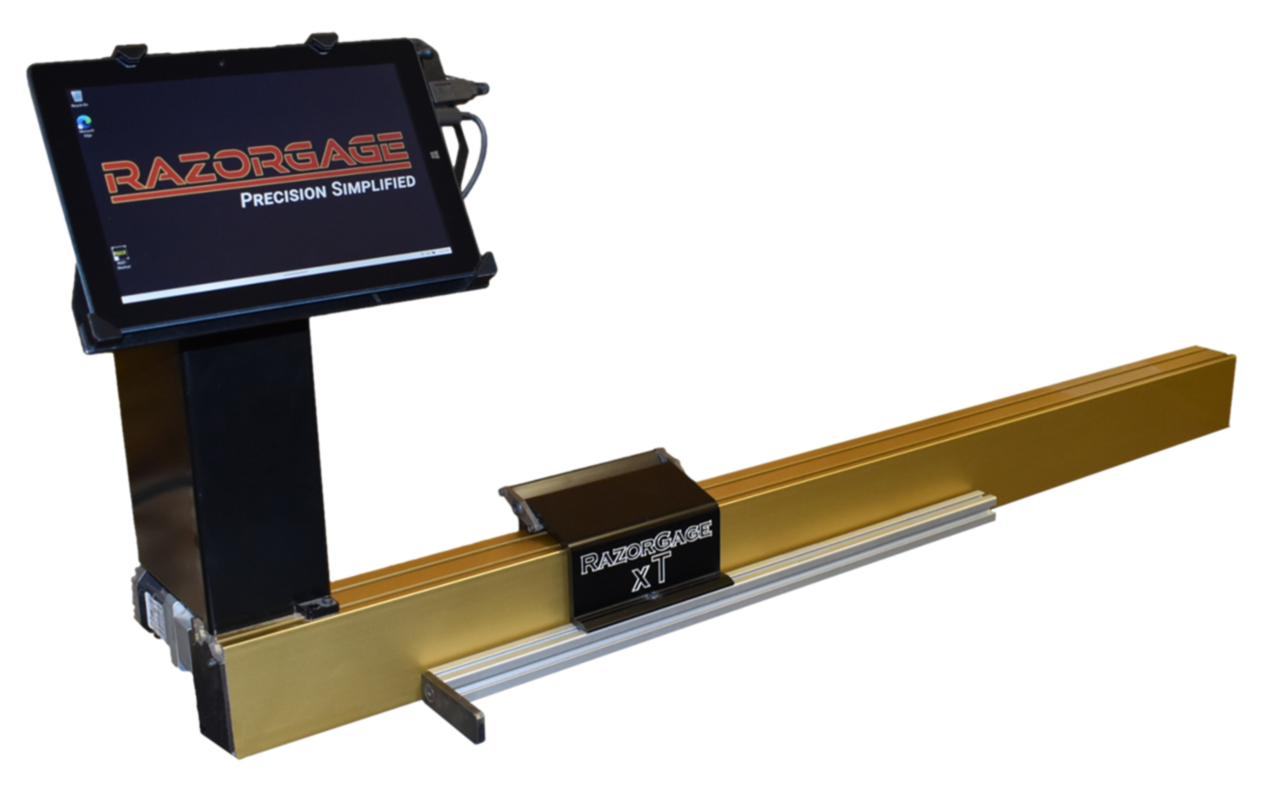

RGxT SAW STOP

RazorGage's entry level digital saw stop eliminates the need for tape measures and manual stops.

RG3 Automatic Saw Measuring System

Material positioner used as an automatic pusher or saw measuring stop. Works with chop saws, autmoatic upcut saws, downcut saws, drill press and more.

Cyclone 600 Upcut Saw

RazorGage's direct drive, upcut saw can cut wood and other materials up to 20" wide with virtually no tearout. Safe and rugged for industrial use.

APS - Auto Pusher System

The APS optimizes your cuts and allows one person to both feed the saw and offload the finished parts.

RazorOptimal Optimizing Saw System

Programmable optimising saw system that scans material for defects and optimizes remaining parts to fit into the defect-free areas, minimizing waste.

RazorOptimal Pocket Hole Saw Systems

Inlcudes scanning and defecting of material plus drills pocket holes, marks layout lines and labels parts to improve operational effciency.

AngleMaster Semi-Automatic Miter Saw System

System automatically adjust to cut your leading and trailing angle allowing effortless, accurate angle cutting.

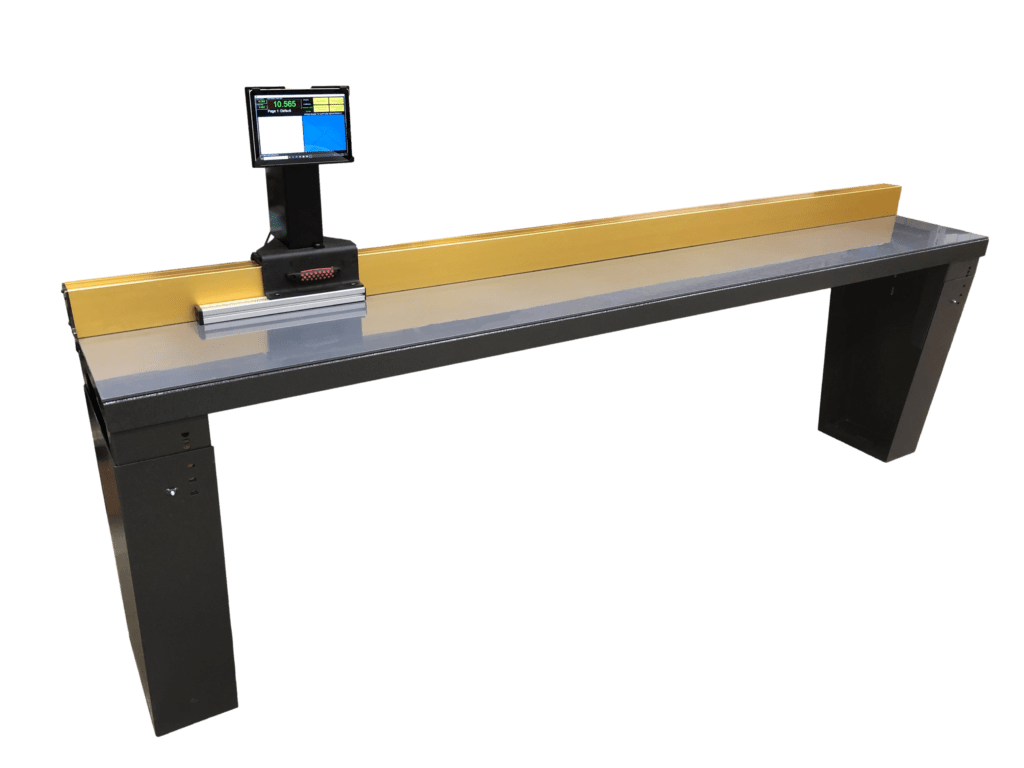

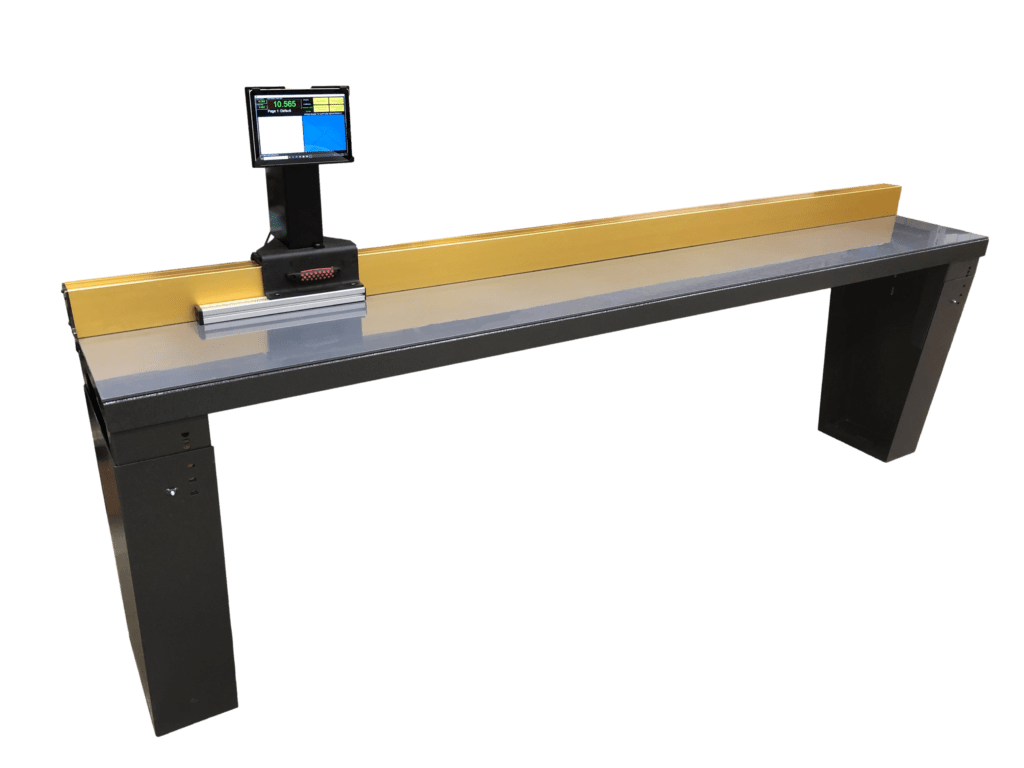

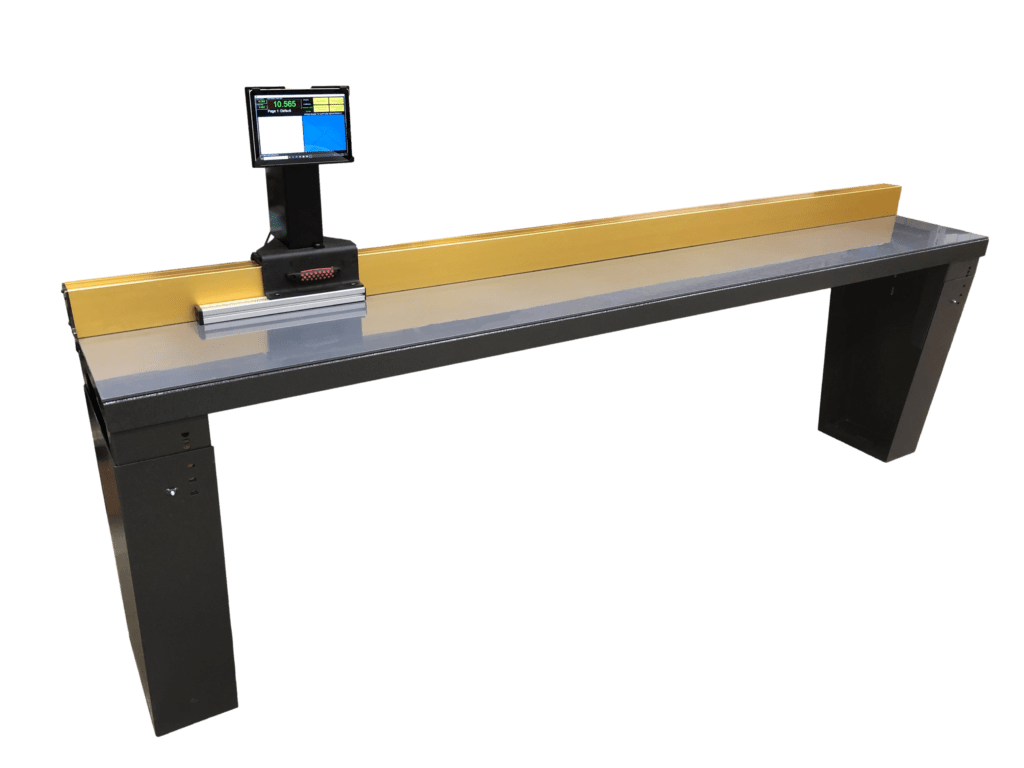

RazorGage Caliper Measuring Table

Reasonably priced, PC-based, single-axis measuring table with many features only found on high-end coordinate measuring machines and expensive precision measuring tools.

Door and Window

RGxT SAW STOP

RazorGage's entry level digital saw stop eliminates the need for tape measures and manual stops.

RG3 Automatic Saw Measuring System

Material positioner used as an automatic pusher or saw measuring stop. Works with chop saws, autmoatic upcut saws, downcut saws, drill press and more.

Cyclone 600 Upcut Saw

RazorGage's direct drive, upcut saw can cut wood and other materials up to 20" wide with virtually no tearout. Safe and rugged for industrial use.

APS - Auto Pusher System

The APS optimizes your cuts and allows one person to both feed the saw and offload the finished parts.

RazorOptimal Optimizing Saw System

Programmable optimising saw system that scans material for defects and optimizes remaining parts to fit into the defect-free areas, minimizing waste.

AngleMaster Semi-Automatic Miter Saw System

System automatically adjust to cut your leading and trailing angle allowing effortless, accurate angle cutting.

RazorGage Caliper Measuring Table

Reasonably priced, PC-based, single-axis measuring table with many features only found on high-end coordinate measuring machines and expensive precision measuring tools.

Commercial Glass

RazorGage's precision systems offer a significant advantage to the Commercial Glass industry, particularly in the fabrication of components that require extremely accurate sizing for secure and professional installation. While glass itself is cut by specialized machinery, the framing components—such as aluminum, vinyl, or wood spacers and structural elements—must be cut with absolute precision to ensure the integrity and fit of large-scale commercial windows, curtain walls, and glass doors. RazorGage's automatic positioners and saw systems ensure that these framing parts are cut consistently to the exact dimensions specified by architectural plans, eliminating the minor, cumulative errors that can lead to costly delays and installation failures.

RGxT SAW STOP

RazorGage's entry level digital saw stop eliminates the need for tape measures and manual stops.

RG3 Automatic Saw Measuring System

Material positioner used as an automatic pusher or saw measuring stop. Works with chop saws, autmoatic upcut saws, downcut saws, drill press and more.

Cyclone 600 Upcut Saw

RazorGage's direct drive, upcut saw can cut wood and other materials up to 20" wide with virtually no tearout. Safe and rugged for industrial use.

APS - Auto Pusher System

The APS optimizes your cuts and allows one person to both feed the saw and offload the finished parts.

AngleMaster Semi-Automatic Miter Saw System

System automatically adjust to cut your leading and trailing angle allowing effortless, accurate angle cutting.

RazorGage Caliper Measuring Table

Reasonably priced, PC-based, single-axis measuring table with many features only found on high-end coordinate measuring machines and expensive precision measuring tools.

Mechanical Contracting

RGxT SAW STOP

RazorGage's entry level digital saw stop eliminates the need for tape measures and manual stops.

RG3 Automatic Saw Measuring System

Material positioner used as an automatic pusher or saw measuring stop. Works with chop saws, autmoatic upcut saws, downcut saws, drill press and more.

Cyclone 600 Upcut Saw

RazorGage's direct drive, upcut saw can cut wood and other materials up to 20" wide with virtually no tearout. Safe and rugged for industrial use.

APS - Auto Pusher System

The APS optimizes your cuts and allows one person to both feed the saw and offload the finished parts.

Furniture

RGxT SAW STOP

RazorGage's entry level digital saw stop eliminates the need for tape measures and manual stops.

RG3 Automatic Saw Measuring System

Material positioner used as an automatic pusher or saw measuring stop. Works with chop saws, autmoatic upcut saws, downcut saws, drill press and more.

Cyclone 600 Upcut Saw

RazorGage's direct drive, upcut saw can cut wood and other materials up to 20" wide with virtually no tearout. Safe and rugged for industrial use.

APS - Auto Pusher System

The APS optimizes your cuts and allows one person to both feed the saw and offload the finished parts.

RazorOptimal Optimizing Saw System

Programmable optimising saw system that scans material for defects and optimizes remaining parts to fit into the defect-free areas, minimizing waste.

RazorOptimal Pocket Hole Saw Systems

Inlcudes scanning and defecting of material plus drills pocket holes, marks layout lines and labels parts to improve operational effciency.

AngleMaster Semi-Automatic Miter Saw System

System automatically adjust to cut your leading and trailing angle allowing effortless, accurate angle cutting.

Get Started with RazorGage

To get started with RazorGage and take your business operations to the next level, view our dealers map or request a quote today.