Calibrating Your RazorGage

Automatic Saw Measuring System

RazorGage is a leader in automatic positioners and saw systems. Our automatic saw measuring systems, programmable saw stops and optimizing saw systems provide the best in efficiency and cutting accuracy. Each RazorGage product is built for precision with the purpose to enhance your processes and transform your operation. Our products use top-of-the-line hardware, intelligent design and powerful optimizing saw software to ensure your cuts are precise, maximizing productivity while minimizing overall waste.

When you purchase your RazorGage saw system, the first step to ensuring accuracy in your operation is to calibrate your machine. However, we often receive questions from customers about how to calibrate the RazorGage. In just a few simple steps your machine can be up and running. Follow along with the steps and a short demonstration video below.

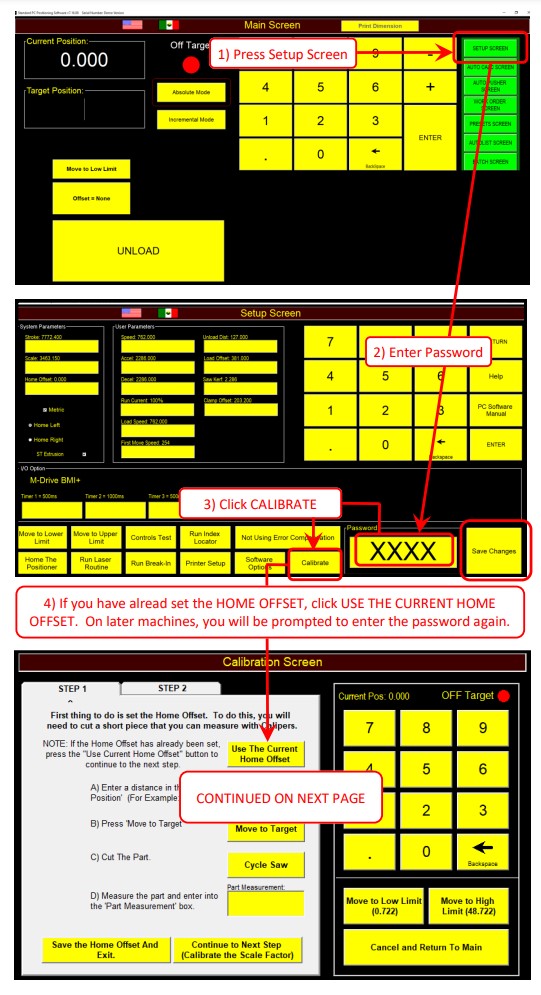

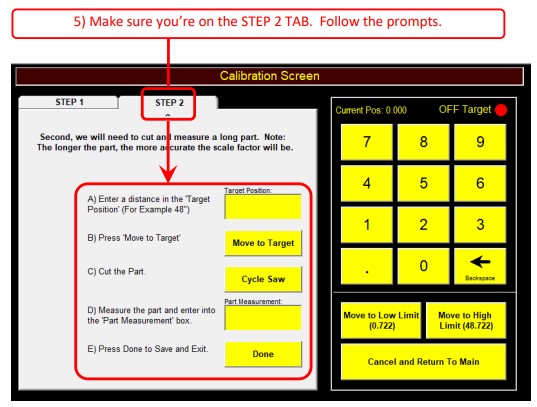

CALIBRATE YOUR RG3 RAZORGAGE

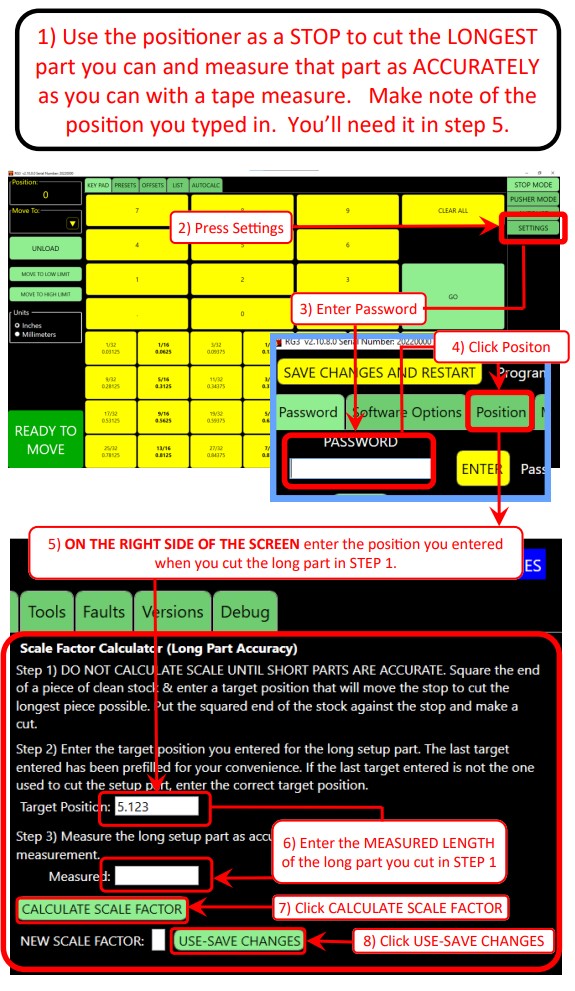

CALIBRATE YOUR ST RAZORGAGE

RG3 - RGST Calibration Procedure

If you are using the RazorGage as a STOP ONLY

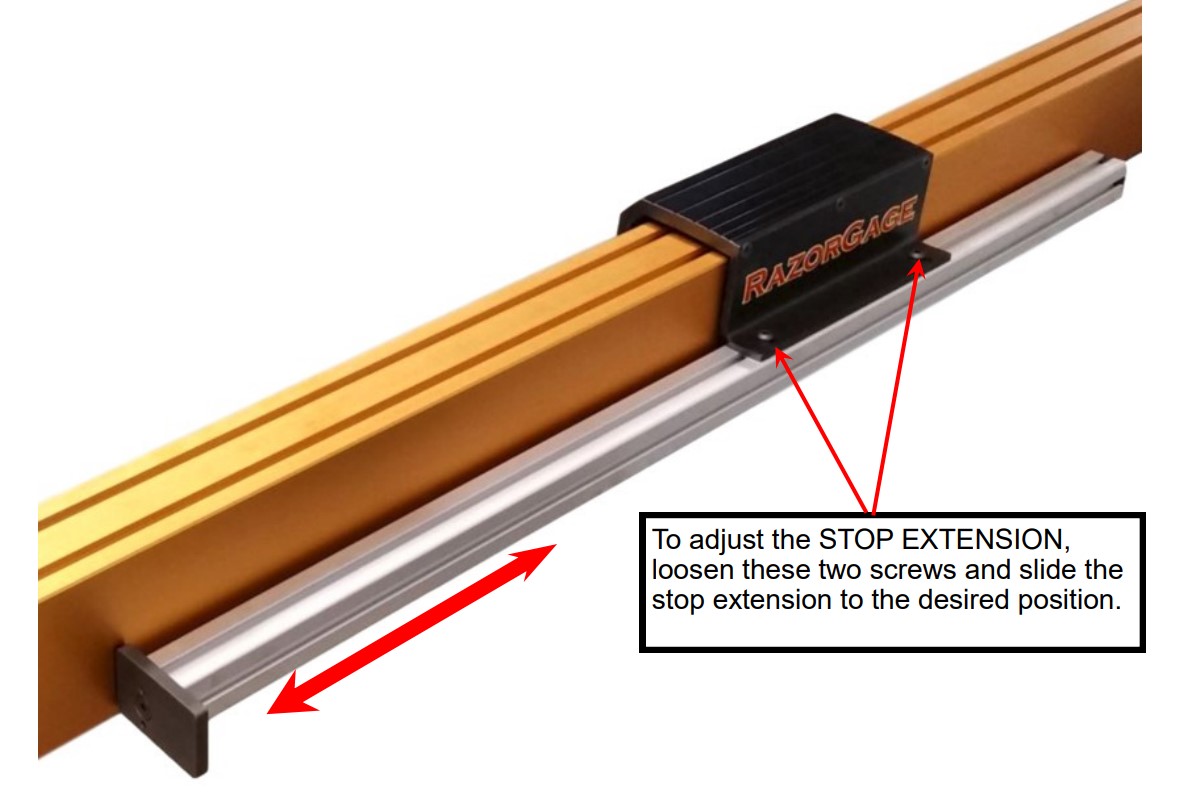

Adjust the STOP EXTENSION only close enough to cut the SHORTEST finished part you ever intend to cut. For example, if you’ll never cut a part shorter than 4”, set the stop 3.5” away from the saw.

If you are using the RazorGage as a PUSHER but it is NOT a RazorGage RazorOptimal or APS.

If you are setting the stop extension on a RazorOptimal

If you are setting the stop extension on a RazorGage APS

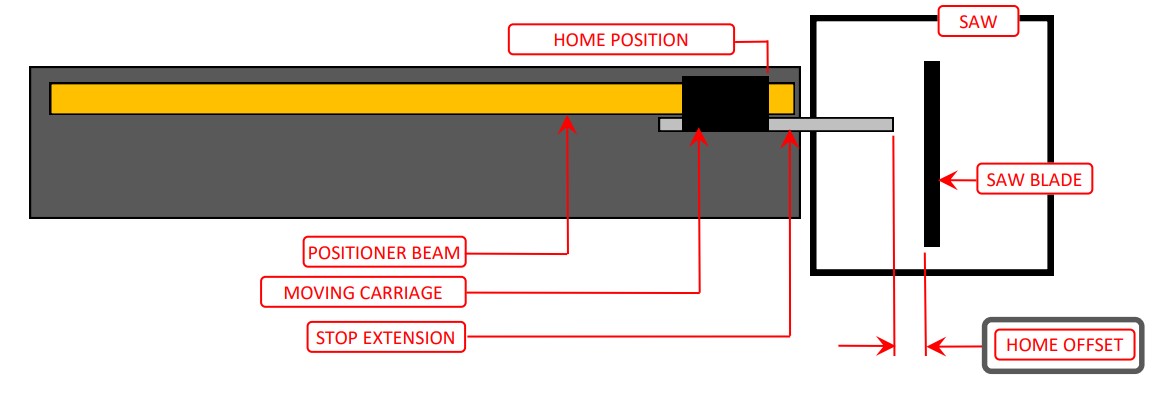

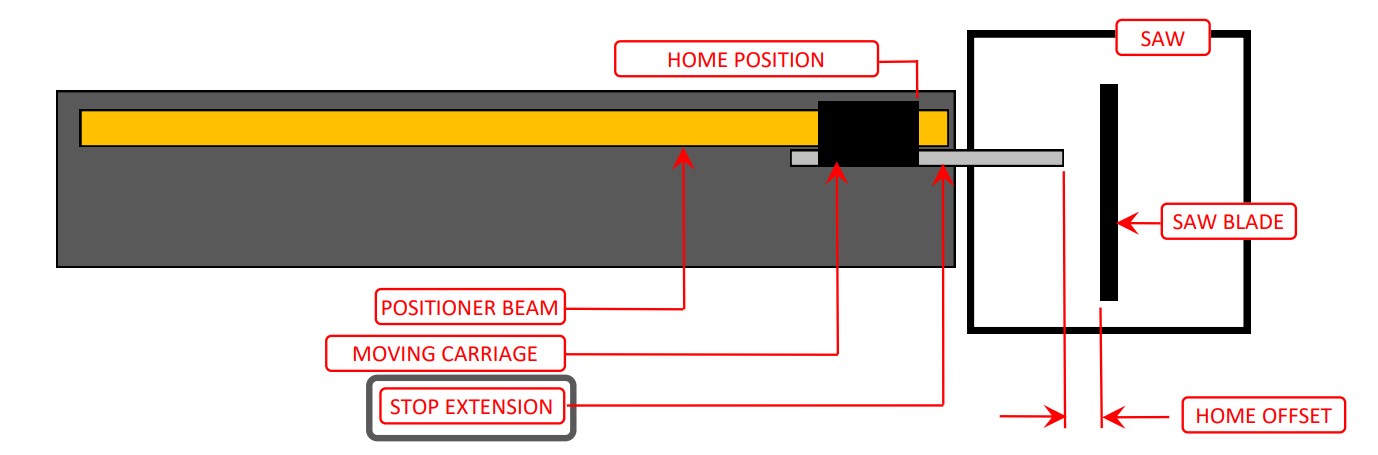

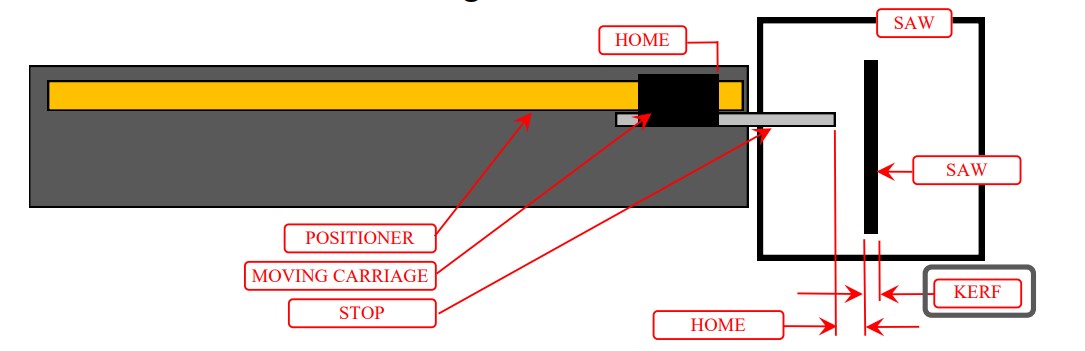

When the positioner is at HOME (LOW LIMIT), the software needs to know where the saw blade is relative to the end of the stop extension. We call that distance the HOME OFFSET.

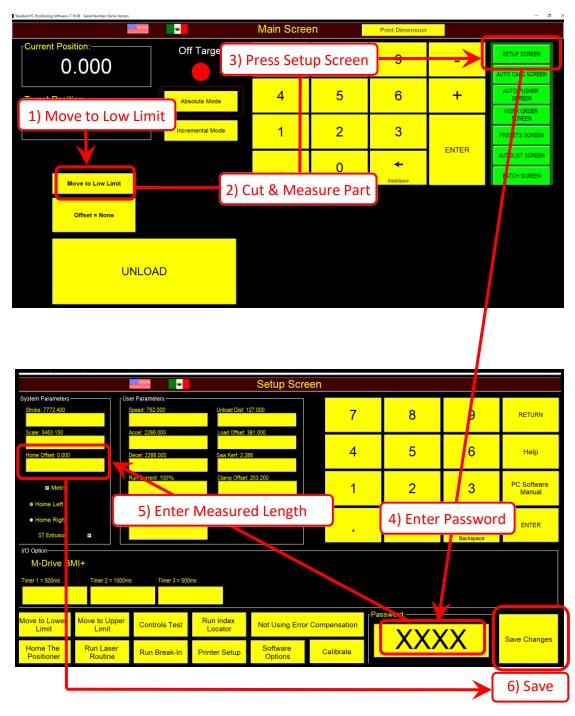

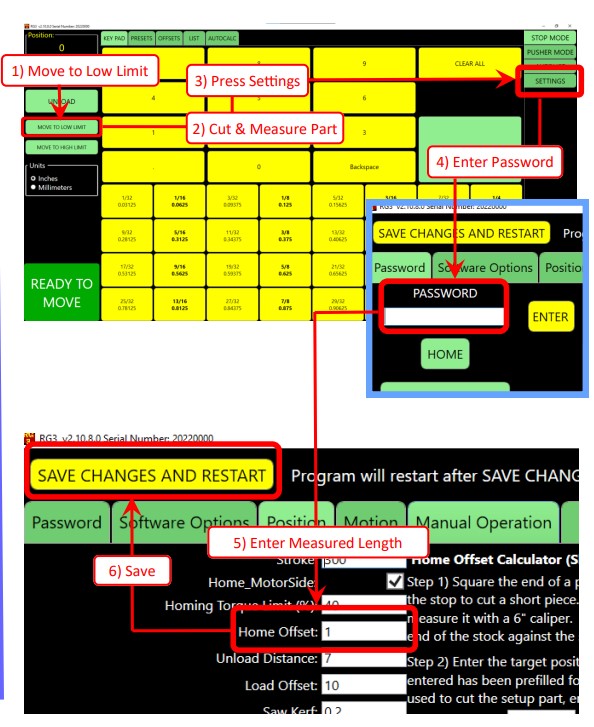

To determine the HOME OFFSET, square the end of a piece of stock, press the LOW LIMIT button in the RazorGage software, place the square end of the stock against the RazorGage stop, and cycle the saw. Measure the resulting part and enter its length as the HOME OFFSET

Setting the SCALE FACTOR

Setting the KERF

Explore Our Products and Accessories

Manufactured in Ames, Iowa, the RazorGage product line is based around our machine tool grade RazorGage ST Automatic Saw Measuring System and our revolutionary Cyclone 600 upcut saw. Our product line also includes optimizing saw systems with crayon defecting, and can include pocket hole drilling and scribe marking for face frame joinery. Our product line is designed to bring maximum efficiency to your operation.

RazorGage also offers a range of accessories to pair with and enhance the performance of your automatic saw measuring system. Each of which can be used with RazorGage saws and saw systems or other saws. Explore these accessories for customizing your saw station!

Learn More About RazorGage Products

View our product support or contact us to see how else RazorGage can help your business. We would be happy to discuss your needs and determine how you can grow your efficiency and operation with RazorGage.