RazorOptimal Pocket Hole

Optimizing saw system with pocket hole Drilling and Cabinet face frame scribing

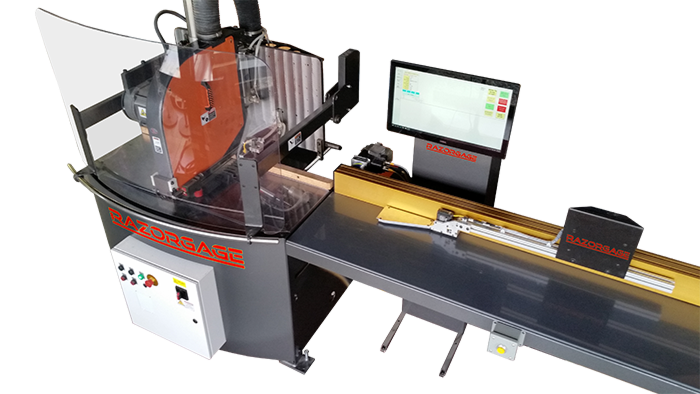

RazorGage produces both a standard RazorOptimal optimizing saw and an industrial pocket hole machine option. With the RazorOptimal pocket hole drilling saw, face frame parts come off the machine ready for assembly making this a great tool for cabinet making.

The RazorOptimal programmable saw system with the industrial pocket hole machine option is just one of our many professional woodworking tools. It is fully customizable and capable of transforming your cutting operation. With the precision of our RazorGage RG3 Automatic Saw Measuring System and the power of our pocket hole drilling down-cut saw, we created a highly accurate, optimizing saw system to streamline your processes unlike any other pocket hole drilling machine on the market.

The RazorOptimal pocket hole cutter features specialized crayon-defecting technology, enabling cut optimization and minimizing the amount of good stock going to waste while attempting to get rid of defective spots. First, the operator marks defects on the material. Then, the saw system scans the material for crayon marks and optimizes remaining parts to fit into the defect-free areas. This automatic defect detection feature means avoiding splits, knots and other wood defects without wasting quality materials.

Ready to learn more about the RazorOptimal?

Using the RazorOptimal Programmable Pocket Hole Drilling Machine

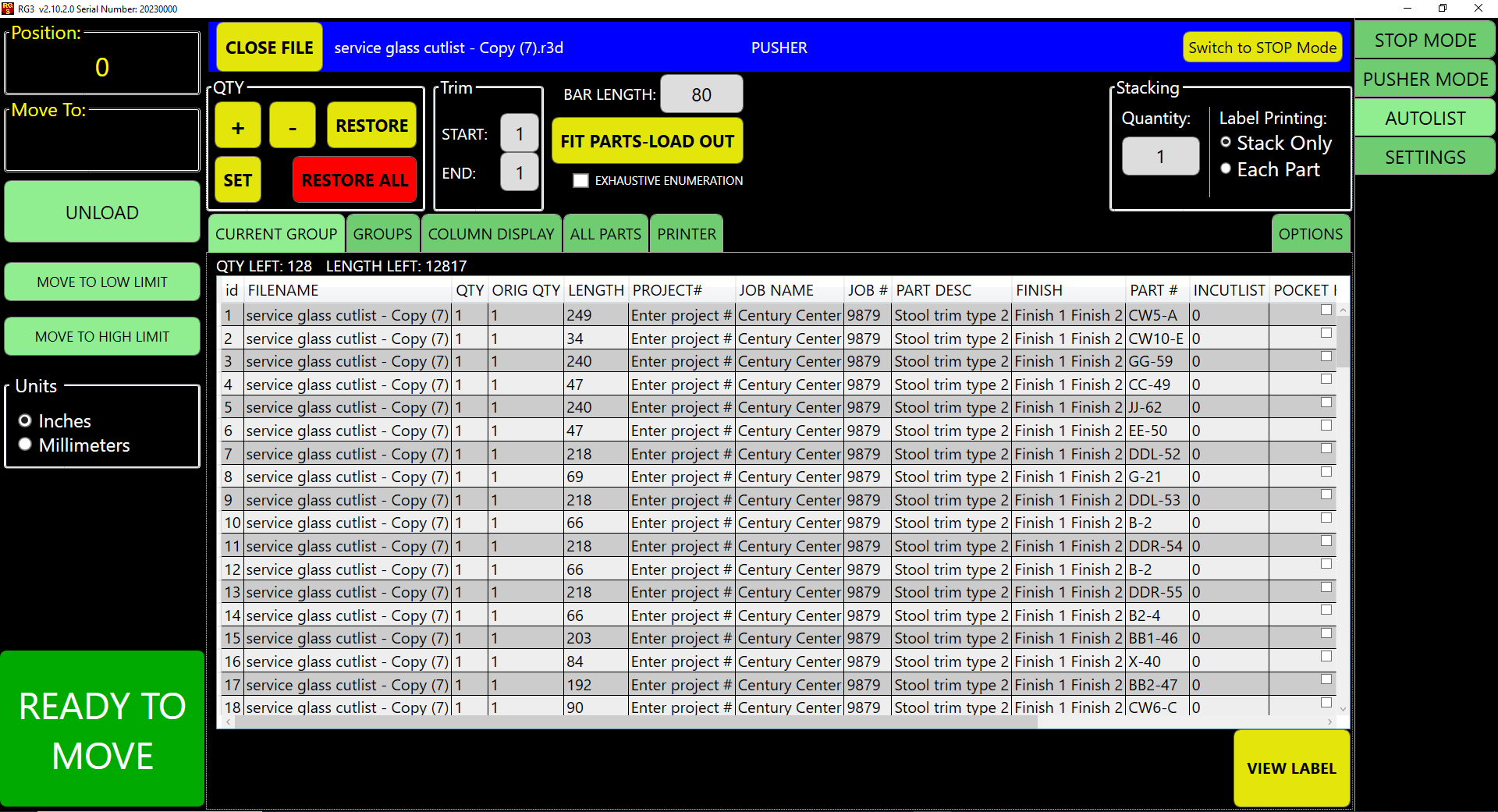

To begin using this optimizing saw with a pocket hole drill, the operator needs to import custom cutlists or use the RazorOptimal software to create cut settings. Once the appropriate cutlist is selected, the operator marks the defects with crayon and the automated pocket hole drilling saw does the rest!

The saw system scans the material for defects and automatically optimizes all cuts to fit within defect-free areas of your material, maximizing the usable area. Then, the pocket hole drilling saw system automatically advances, cuts lineal stock, drills pocket holes, scribes face frame layout lines and prints the part information directly on your material.

Making Cabinet Face Frames With the RazorOptimal

If you’re in the market for a cabinet saw, the RazorOptimal Pocket Hole is a wonderful option that can take your woodworking to the next level. It has easy-to-operate cutting systems that improve quality and productivity for cabinet manufacturing.

A lot of tools for cabinet making require manual operation. With the RazorOptimal Cabinet Saw with pocket hole drilling, you can easily build and assemble cabinet face frames in a matter of minutes. See what other tools for cabinet making we offer at RazorGage!

RazorOptimal Pocket Hole Saw System By RazorGage | A Full Demonstration

Pocket Hole Drilling and Face Frame Scribing With the RazorOptimal

Two main features set this RazorOptimal saw system apart from our standard RazorOptimal unit: pocket hole drilling and face frame layout scribing.

If you purchase the RazorOptimal with the pocket hole drilling option, the saw system will be equipped with a 3-spindle pocket hole drill gear drive spindle cartridge located to the left and right of the main saw blade. Drill up to 2 pocket holes at a time, depending on your needs. Unlike other standalone pocket hole drilling machines, this feature is built right into the main saw system, maximizing efficiency and saving you the cost of purchasing additional equipment.

Face frame layout scribing is another feature unique to the RazorOptimal with pocket hole drilling option. This optimizing pocket hole saw system can produce enough face frame parts for 30 face frames per hour.

Two days of installation and training are included with the purchase of all RazorOptimals (US or Canada only). We also work with leasing partners to offer RazorGage products at an affordable monthly payment. Get in contact with us today to find out how you can benefit from our optimizing pocket hole saw. Request a quote from RazorGage.

Additional RazorOptimal Pocket Hole Saw Features

- Windows Tower PC operation on a large, color hi-resolution touchscreen monitor.

- Easy to use software with room to store thousands of cutlists. Optimize and sort cutlists into thousands of groups according to multiple criteria.

- Optimized defect detection technology maximizes usable material between crayon marked defects

- Automatic top, left and right intelligent clamping

- Paper label printing or printing directly on material

- Part length accuracy varies with application but +/-.005" is possible

- Optional RazArray sorting light grid can be added to further improve operational efficiencies and reduce mistakes

Optimizing Your Pocket Hole Machine Software

Our industry-leading software is powered by Microsoft Windows, so networking and file sharing is seamless between the RazorOptimal software and other PCs in your office, home, or shop.

The RazorGage programmable pocket hole machine software is based on a rapid development platform, and we are constantly evolving and improving it to meet the needs of our customers. It is also customizable and can be adapted to suit a variety of applications and projects.

Options & Accessories for the RazorOptimal Pocket Hole Saw

Ink Jet Printer

Print directly on parts to

keep them organized.

RazArray Sorting Assist

Helps you organize parts as they

come off the RazorOptimal.

Testimonials

"The RazorOptimal has totally changed how we produce our frames, our door boxes and any linear stock we need in set lengths. It's an amazing machine."

Phil Crabtree

Cabaxis

Owensboro, Kentucky