RazorGage Saw Optimization Software

Software for Computerized Saw Systems

Everyone uses personal computers these days. Why should your automatic saw measuring system be different? All RazorGage computer controlled saw systems include a reliable graphical user interface with built-in Wi-Fi.

RazorGage builds computerized saw positioners with a Windows interface, offering intuitive operation that nearly eliminates the need for training. Parameters have sensible names like SPEED, KERF, ACCEL, & DECEL, so you don’t need a manual to understand the settings. Most operators can figure out the saw optimization software with just a few minutes of practice.

With superior software and advanced hardware, RazorGage systems are equipped to handle any job with ease. Learn more about RazorGage products and the software that powers them.

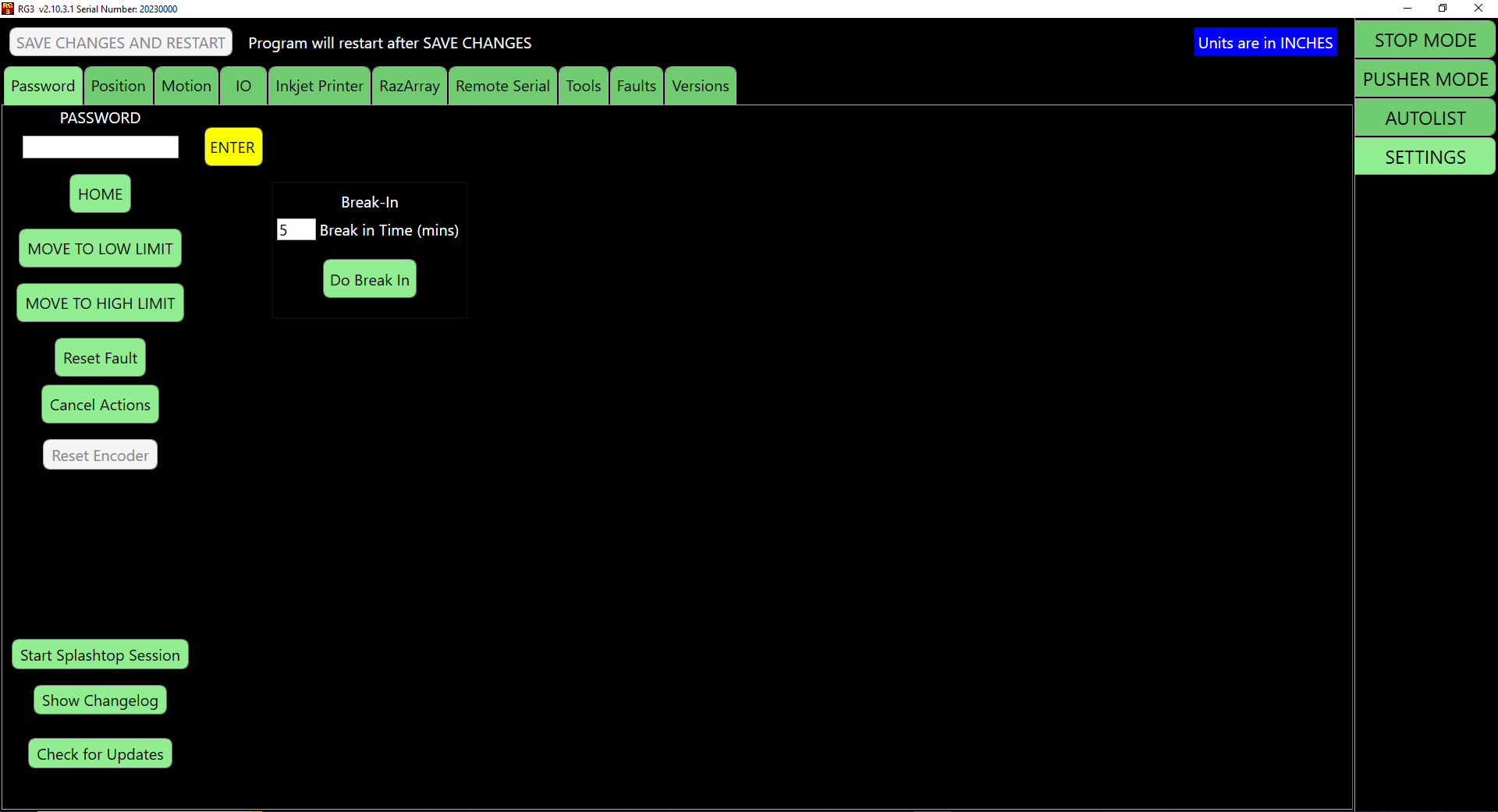

RG3 WINDOWS PC SAW OPTIMIZATION SOFTWARE

As you have come to expect from RazorGage, the Windows computer controlled RG3 saw software provides the same bright, bold user interface as our previous software. There are no menus to memorize. Operation is obvious. Setup and calibration functions are just a screen touch away. Built-in functions such as fraction keys and pages of Presets are standard but the RG3 software has been streamlined to make it even simpler to operate, helping to eliminate operator mistakes and improve productivity.

There are just 4 tabs used to operate the system. You can choose between Stop Mode or Pusher Mode depending on what your cutting operation calls for. AutoList is our optional optimizing software upgrade you can include at any time to optimize yield on your expensive material. There are multiple tabs within the Settings tab that help you properly set up your RazorGage positioner or saw system to perform all the functions you are expecting.

Networking and file sharing using the RazorGage RG3 software is no different than any other PC in your office, home, or shop. Since the RazorGage RG3 software is based on a rapid development platform, it is constantly evolving to meet the needs of our customers and can be easily customized.

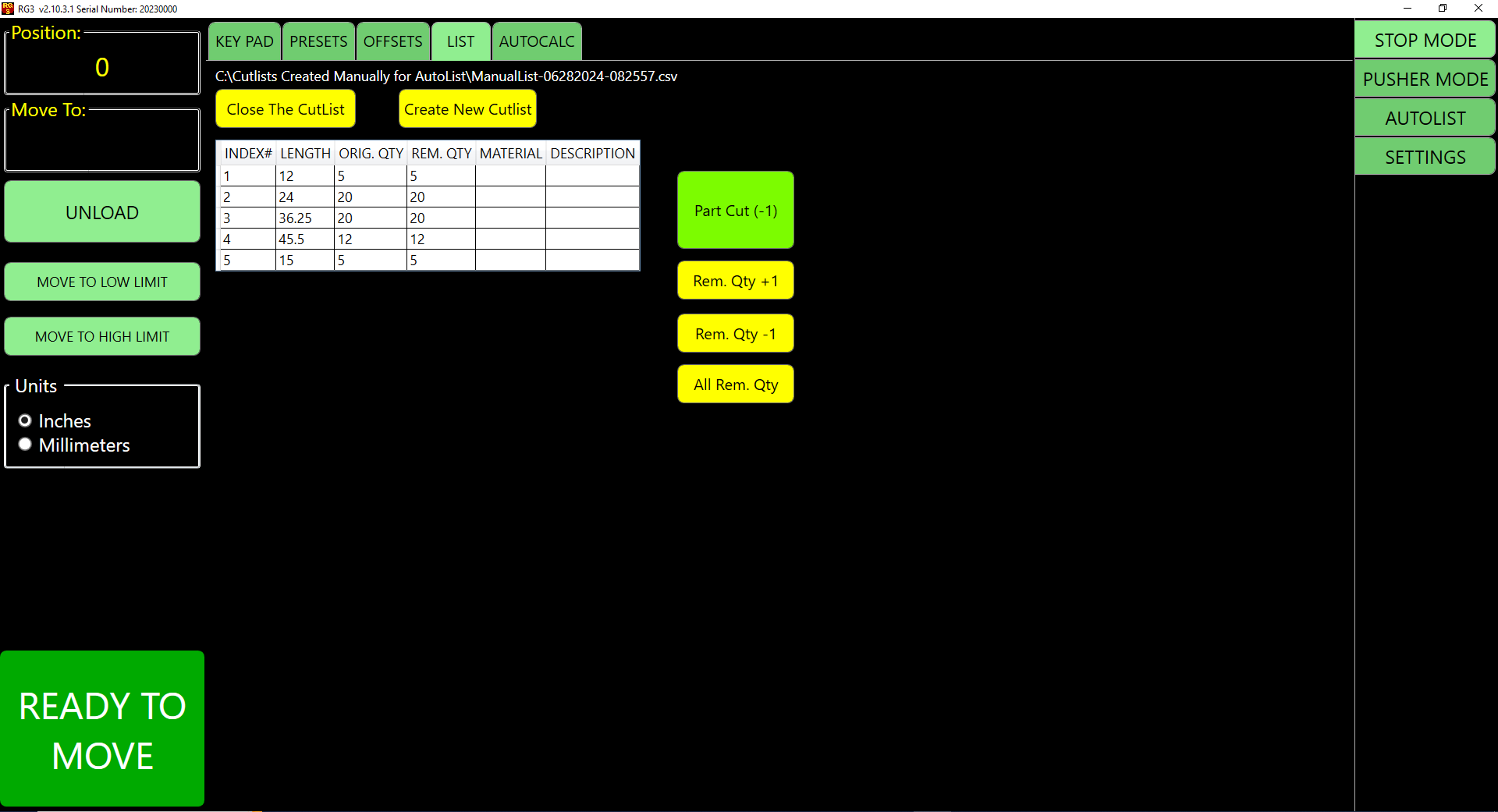

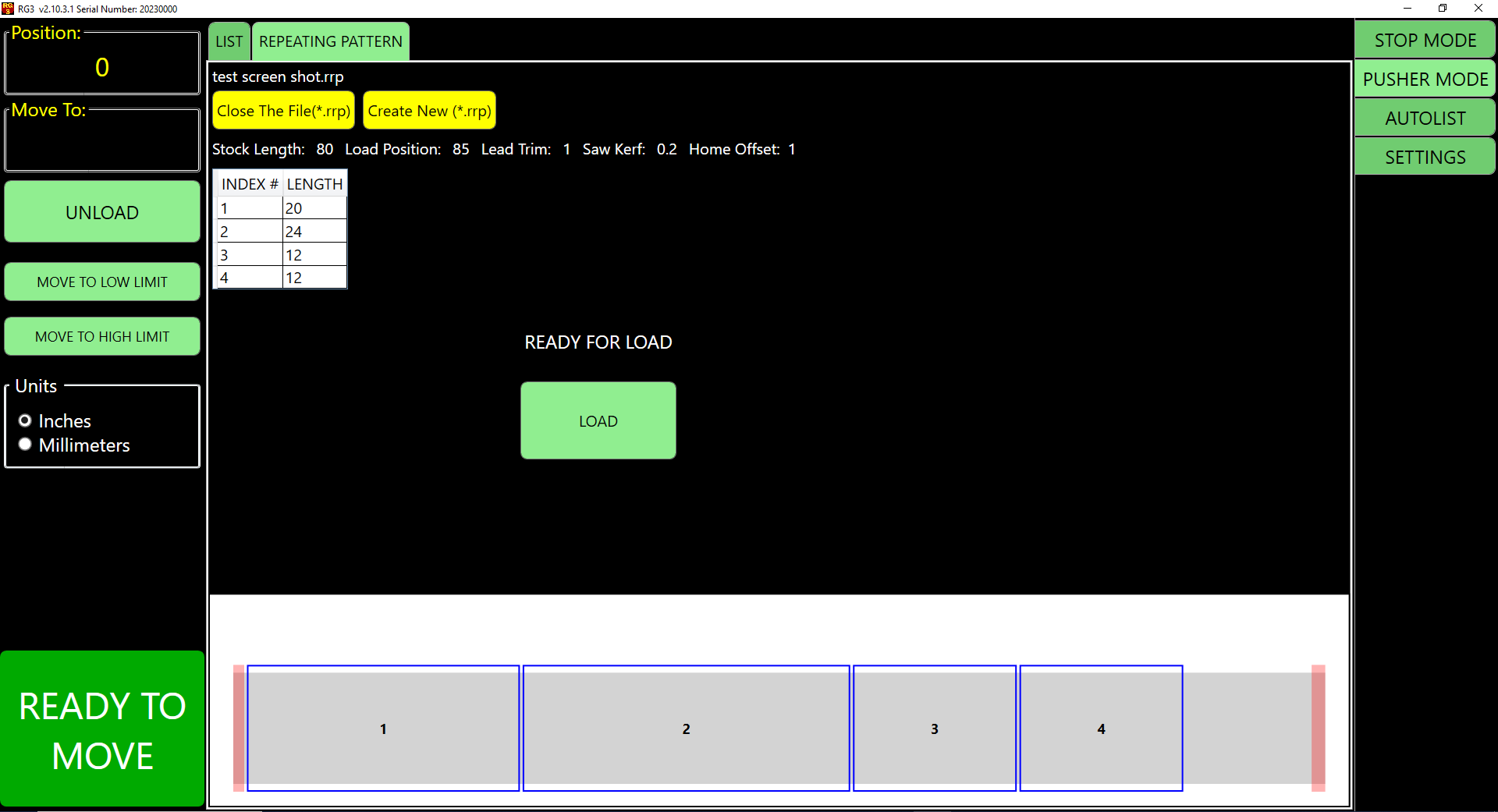

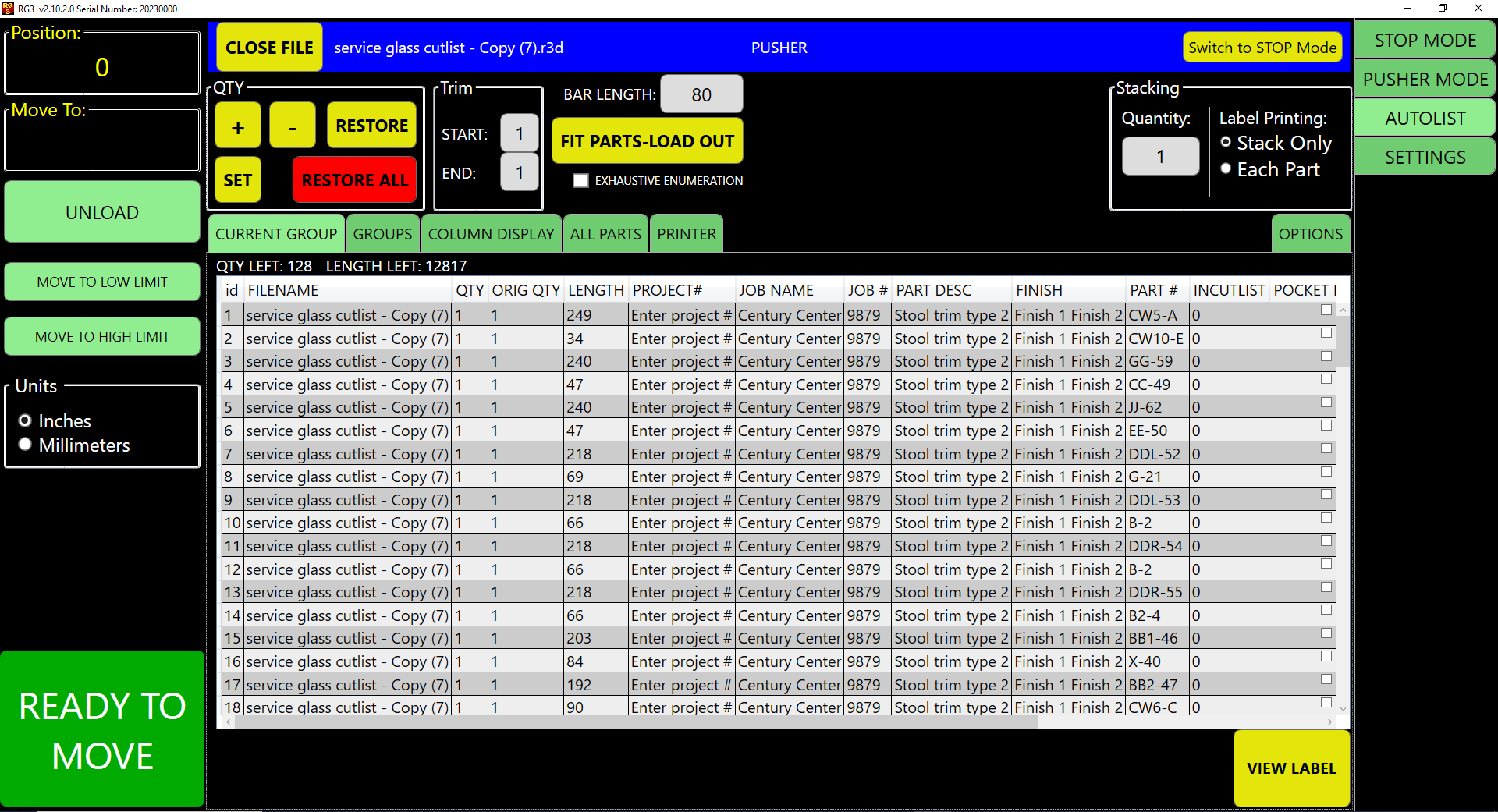

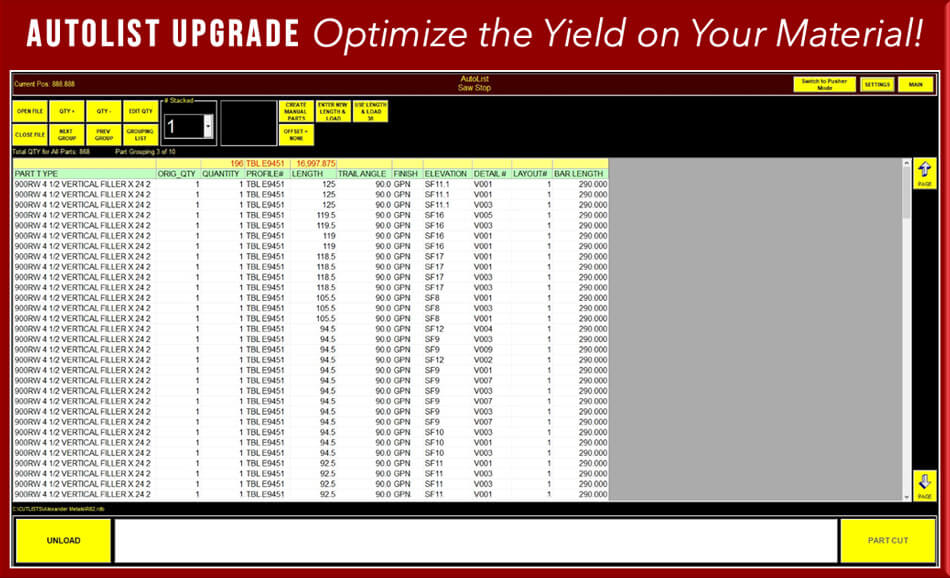

AUTOLIST is our optional optimizing saw software that reduces waste material, saves time and expense.

The AutoList screen can be mapped to accommodate delimited files with unlimited columns in any order, will sort that list by multiple criteria, and then calculate optimal cutting solutions to maximize yield on your valuable material. Multiply cutlist quantities by a different factor each time you open.

Switch between Pusher Mode & Stop Mode any time. As a stop, just touch a line item and the RazorGage moves to position. Pressing the PART CUT button decrements quantity. Items are crossed off when the quantity reaches zero. As a pusher, enter available clear length for an optimized solution.

If you want to print labels for your parts, the RG3 AutoList allows you to print labels for each part or, if you are stacking your material, you can choose to have one label printed for each stack. If you want custom labels for your cutting operations, custom label design software is available for the RG3 AutoList software.

With the ToolSafe option, part quantities can be automatically decremented when the part is cut. When a part quantity reaches zero, the part is crossed off and the automatic saw measuring system advances to the next dimension in your list.

SETTINGS tab contains multiple tabs that help you properly set up your RazorGage positioner or saw system to perform all the functions you are expecting.

The Password tab contains many of the functions to perform when updating the software, homing the RazorGage and diagnosing problems. One significant improvement with the RG3 is that you don’t have to Home it all the time. The RG3 has a battery and remembers where the motor was when the power is off.

The Position tab is where all the cutting parameters are applied specific to your cutting requirements. Settings such as Stroke, Home Offset, Load Offset, Saw Kerf, and Scale Factor need to be determined and input into the RG3 software allowing the RazorGage to deliver the accuracy you require and expect.

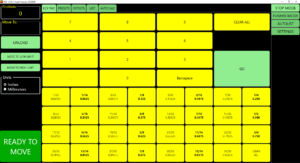

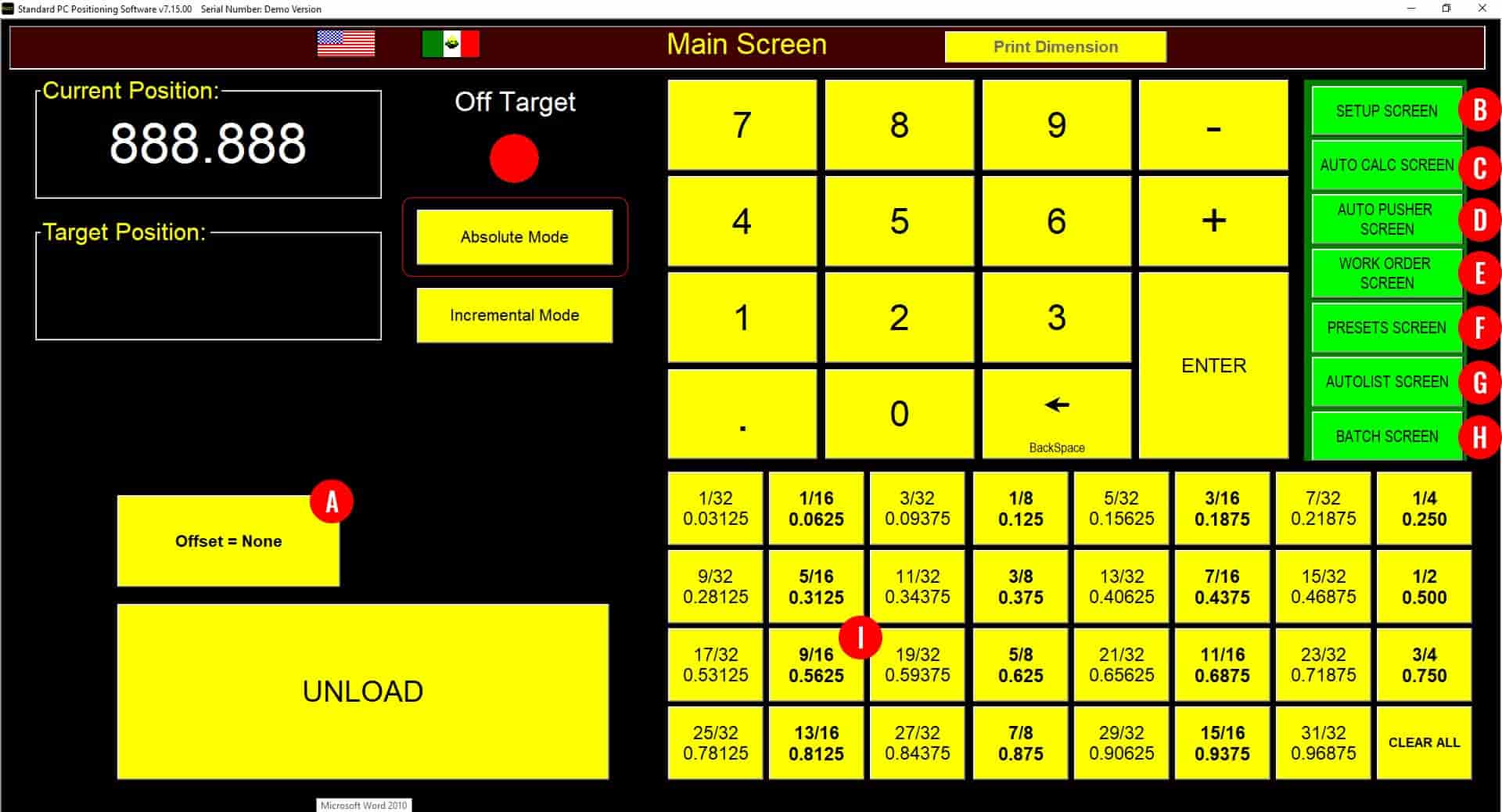

ST WINDOWS PC SOFTWARE

Provided on Razorgage ST Positioners and Optimizing Saw Systems from 3/2009 – 12/2022

The Windows computer controlled saw software provides a bright, bold user interface. There are no menus to memorize. Operation is obvious. Setup and calibration functions are just a screen touch away. Built-in functions such as fraction keys, pages of Presets, the Work Order screen, the Auto-Pusher screen and the Batch screen, help eliminate operator mistakes and improve productivity. Upgrade a ST-Windows platform to include AutoList at any time to optimize yield on your expensive material.

Networking and file sharing using the RazorGage software is no different than any other PC in your office, home, or shop. Since the RazorGage software is based on a rapid development platform, it is constantly evolving to meet the needs of our customers and can be easily customized.