Stop Wasting Wood! The Definitive Saw Measuring System Review

Traditional cutting setups rely on manual measurements, physical rulers, and constant adjustments. Every shop we talk to deals with the same problems: wasted material, operator errors, inconsistent output, and the rising cost of lumber. When everything depends on the operator’s eyes and tape measure, mistakes add up quickly.

Modern production environments demand better accuracy and better efficiency. That’s why more shops are turning toward an Automatic Saw Measuring System to reduce waste and simplify workflow. In this review, we’ll break down the essential features, the major benefits, and what you should consider before adopting a measuring system for your shop.

Why Manual Measurement Leads to Waste

Manual measurement depends entirely on human accuracy, and even your best operators will see variation over time. Re-measuring the same board slows the job down and wears people out. Small mistakes start stacking up, an eighth of an inch here, a misalignment there, and suddenly you’re short on parts or tossing expensive material.

Each job change forces more resets, leading to lost time and inconsistent output. Different shifts and operators produce different results, which makes it impossible to guarantee repeatability. The gap between traditional tape-measure setups and modern production expectations keeps growing, and it’s costing shops real money.

How an Automatic Saw Measuring System Helps

An Automatic Saw Measuring System eliminates guesswork by giving operators precise, repeatable measurements for every cut. Instead of checking and rechecking lengths, they position the material once and cut with confidence. That accuracy reduces scrap and ensures consistent material utilization across the entire job.

Measuring systems also streamline workflow. Fewer resets mean fewer interruptions. Whether you’re running a standalone manual saw or an automated setup, the system maintains accuracy so operators can focus on cutting, not chasing measurements. When paired with digital tools, shops can manage cut-lists, track jobs, and even avoid defects during planning.

Key Features of a Quality Automatic Saw Measuring System

Precision and Repeatability

A high-quality Automatic Saw Measuring System gives consistent, accurate positioning with minimal error from one cut to the next.

Compatibility

It should work with a wide range of saw types, manual chop saws, upcut saws, or integrated automated systems like APS or RazorOptimal.

Ease of Use

Simple controls, quick calibration, and intuitive operation help teams get up to speed fast.

Safety

When combined with hands-free clamping or automated systems, the operator’s hands stay away from the cutting zone. The measuring system alone doesn’t replace blade-safety requirements.

Optional Software and Automation

Cut-list handling, batch processing, and workflow tracking create smoother, more organized production.

Durability

Heavy-duty construction, stable rails, and solid mechanics ensure a long service life, especially important in high-volume environments.

Benefits of Using an Automatic Saw Measuring System

- Reduced Waste: Accurate measurements maximize usable board length.

- Higher Efficiency: Operators keep cutting instead of repositioning material.

- Operator Ease: Less bending, rechecking, and physical strain.

- Safety: Integrates with hands-free clamping to keep operators away from the blade zone.

- Consistent Output: Uniform parts lead to easier assembly and a cleaner finished product.

- Scalability: Works for single-saw setups or fully automated production lines.

- Data-Driven Workflow: Digital integration helps track cuts, jobs, and overall efficiency.

Choosing the Right Automatic Saw Measuring System

Choosing the right system comes down to understanding what your shop truly needs.

Assess Shop Needs

Look at your production volume, material types, job variety, and workflow layout.

System Types

- Basic positioners for small shops

- Automated pushing systems for continuous production

- Fully integrated setups for complex multi-part operations

Compatibility Checks

Confirm your saw design, length capacity, space availability, and power needs.

Installation & Training

A good system should have a short learning curve and integrate easily into your existing workflows.

ROI Measurement

Track material saved, errors eliminated, and time gained to understand the long-term value.

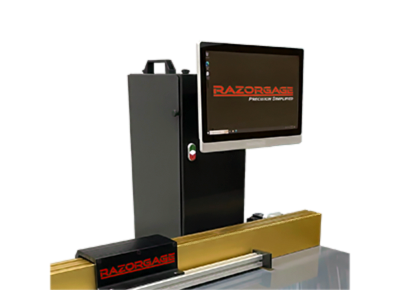

RazorGage: Durable Engineering and Trusted Performance

RazorGage builds measuring systems with long-lasting, heavy-duty components. Our systems use precise linear rails, smooth motion control, and planetary gearheads designed for accuracy. Shops across woodworking, aluminum, metal fabrication, and manufacturing rely on RazorGage for reliable, repeatable cuts.

We also offer optional integration with APS or RazorOptimal for shops that need automated pushing or full optimization of Automated saw systems. Our support includes installation guidance, calibration assistance, and ongoing help whenever you need it. The goal is always the same: durable performance and consistent accuracy over years of daily use.

Before You Buy: Key Considerations

Before investing in an Automatic Saw Measuring System, make sure you evaluate:

- Budget: Compare upfront cost with long-term material savings

- Shop Fit: Space, saw style, production flow

- Support & Training: Availability of setup assistance and software updates

- Infrastructure: Power layout and safety requirements

- Future Growth: Ability to scale into automation later

- Maintenance: Durable construction reduces upkeep and protects accuracy

- ROI Outlook: Measure efficiency gains, waste reduction, and output improvements

These factors help you choose a system that works today and still works years from now.

Conclusion

Manual measurement drains time, increases waste, and limits what your shop can produce. An Automatic Saw Measuring System changes that overnight. With accurate positioning, consistent results, and streamlined workflow, you get better material usage, stronger consistency, and smoother production.

Precision becomes effortless. Consistency becomes the norm. And productivity becomes something you can depend on. Investing in the right measuring system isn’t just an equipment upgrade; it’s a shift toward modern, efficient, dependable production.

H2: Get Accuracy You Can Count On

If your shop is ready for better accuracy, less waste, and more predictable output, we’re here to help. Request a RazorGage demo or quote to see how our measuring systems can improve your workflow.

Contact us today to get started.

H2: FAQs

How does an Automatic Saw Measuring System reduce waste?

It positions material accurately so every cut uses the board efficiently.

Can it integrate with automated systems?

Yes, RazorGage systems pair with APS and RazorOptimal for automation.

Does it improve consistency across shifts?

The system ensures repeatable accuracy no matter who operates it.

What types of saws is it compatible with?

It works with manual saws, upcut saws, and automated platforms.