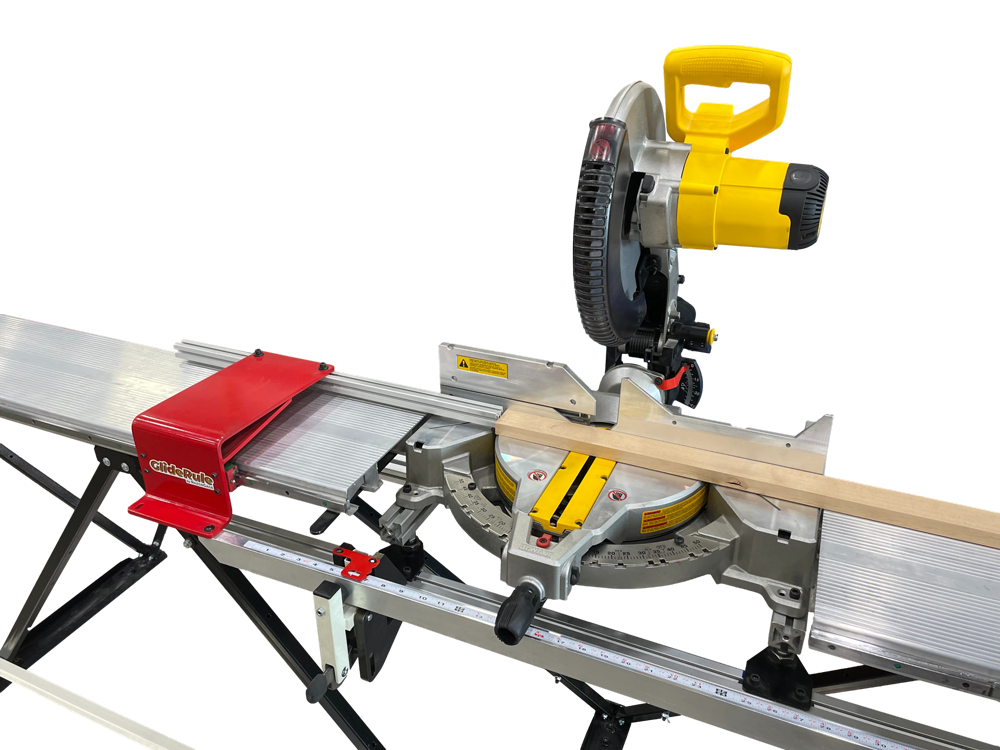

RAZORGAGE GLIDERULE CHOP SAW STATION

CUSTOMIZABLE SAW STOP

The GlideRule Chop Saw Station is an economical material stop that offers many of the advantages of the expensive motor driven stops. What sets GlideRule apart is the method for adjusting the stop. Unlike other manually adjusted stops, the operator can adjust and lock the stop without moving from the sawing position.

Ready to learn more about how to operate the GlideRule and available options to expand the functionality of this chop saw station?

Using the RazorGage GlideRule

Chop Saw Station

The operator adjusts the stop’s position with a bar that runs across the front of the saw station. A locking brake with a cursor is positioned over a graduated scale on top of the bar. You simply slide the bar to the desired length for your cut, lock it in place, place your material against the stop and make your cut. With the adjustable stop extension that can reach the blade, GlideRule can be set to cut as short a part as you want.

This chop saw station includes extruded aluminum infeed and outfeed tables, bolted to rigid modular truss sections. Slotted rails supported on height adjusting threaded stanchions provides the adjustability required to accommodate chop saws of nearly all widths, depths, and heights.

Contact us today to learn a better way to measure and cut your parts consistently without ever leaving the saw station. Request a quote from RazorGage today.

RazorGage GlideRule Chop Saw Station Features

- Works with all brands of chop saws

- Recirculating ball bearing blocks spaced 6 inches apart for excellent rigidity.

- Smooth adjustment as industrial grade bearing blocks slide on a hardened and ground steel rail

- Design allows for mounting any style fence to the tables

- Adjustable stop extension that can reach the blade

- Adjust and lock the stop without moving from the sawing position

- Optional tablet offers optimizing software, cutlist download, label printing and push cutting

- Available in 8’ & 11’ Stroke

Optional Tablet & Software Expands Functionality

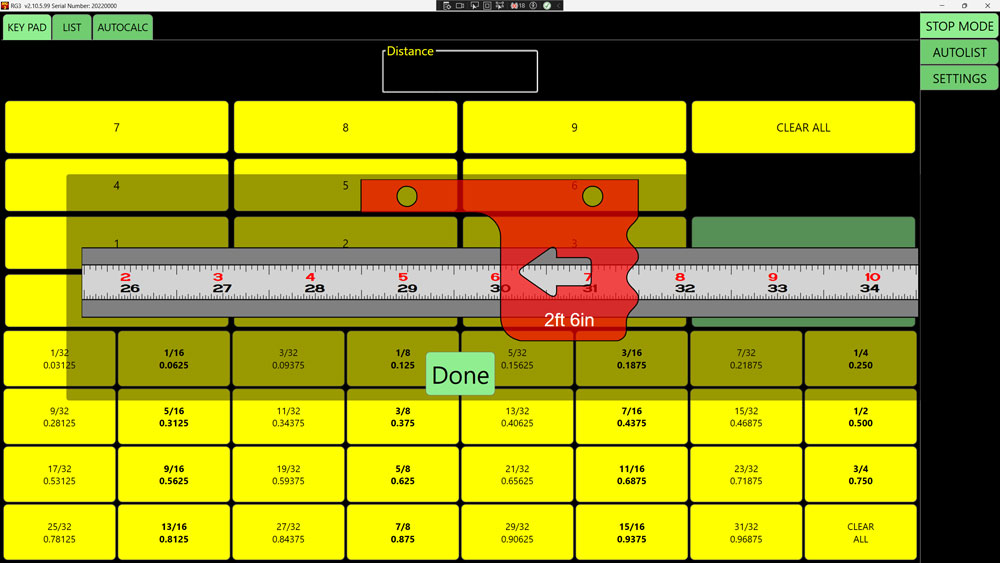

Stop Mode – Key Pad

SELECTED LENGTH – On this screen you enter the cut length for your board.

To minimize scale reading errors, the screen displays an image showing the position of the GlideRule scale and cursor as it should look on the actual scale that you manually adjust.

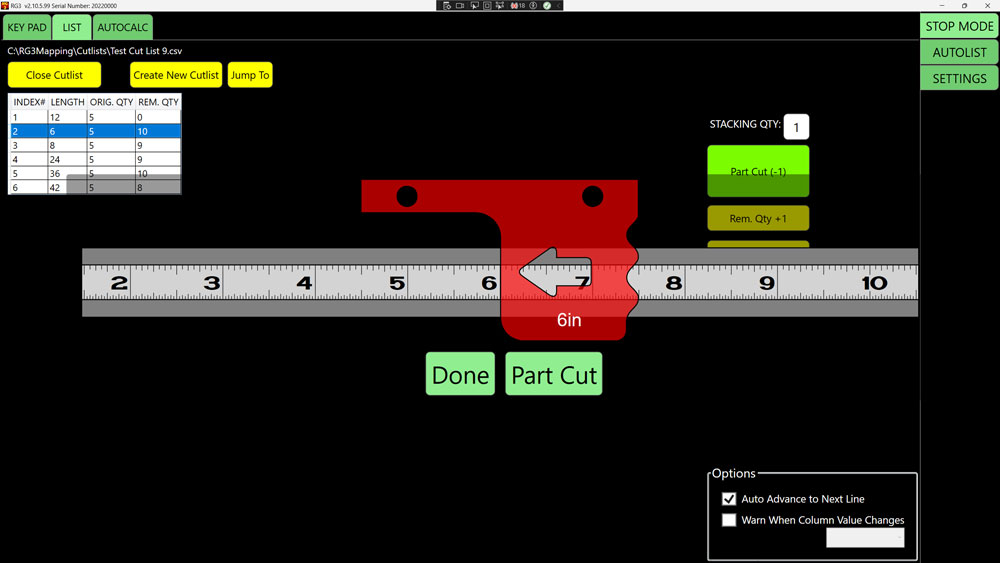

Stop Mode – List Screen

SELECTED CUT - On this screen, you select the desired length from a pre-determined cutlist.

To minimize scale reading errors, the screen displays an image showing the position of the GlideRule scale and cursor as it should look on the actual scale that you manually adjust.

AutoList

SELECTED CUT - On this screen, you select the desired part from a pre-determined cutlist. A cutlist in the AutoList screen displays more part information than you see in the List Screen.

To minimize scale reading errors, the screen displays an image showing the position of the GlideRule scale and cursor as it should look on the actual scale that you manually adjust.

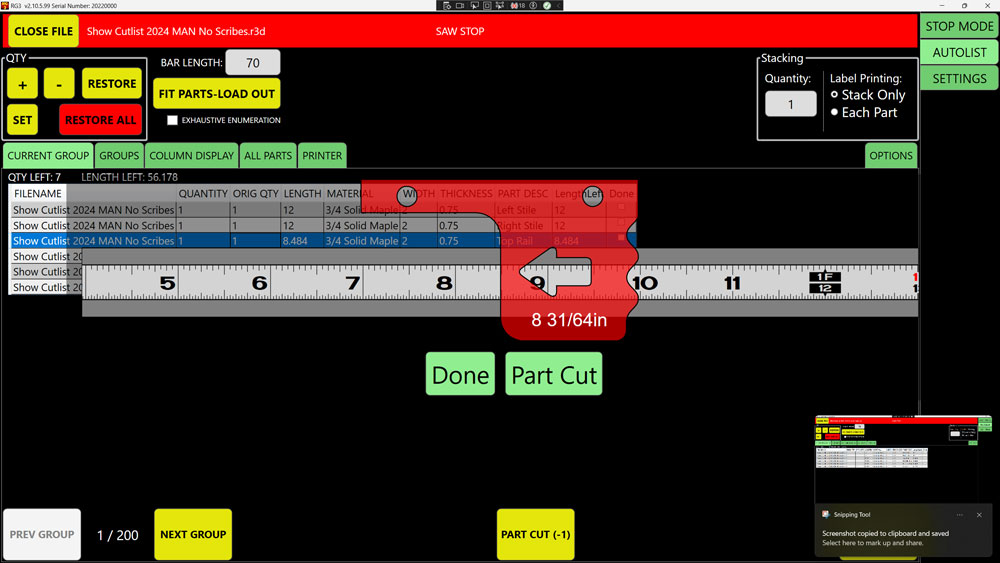

Autolist

OPTIMIZED RUN - On this screen, based on the total length of your raw material, your stop positions are optimized and predetermined from the selected cutlist, reducing waste material.

To minimize scale reading errors, the screen displays an image showing the position of the GlideRule scale and cursor as it should look on the actual scale that you manually adjust.