RazorGage Automatic Saw Systems

Maximizing efficiency for your cutting operation

We provide the tools for accurate, reliable and productive cutting operations.

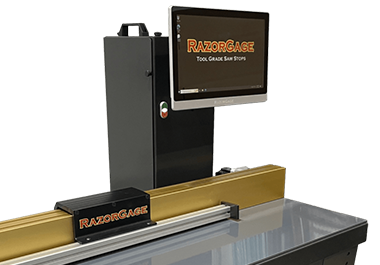

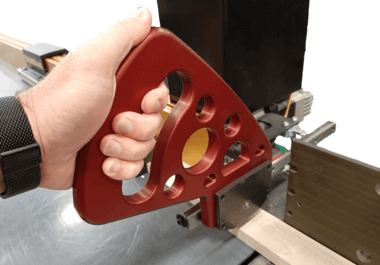

The RazorGage product line is based on a modern state-of-the-art automated material positioning system. Our machine tool grade, programmable saw stops and pusher systems have set a new standard for accuracy, repeatability and dependability. The upper end of the product line includes optimizing cut-off saw systems with crayon defecting, and can include pocket hole drilling and scribe marking for face frame joinery.

RazorOptimal

With the precision of our RazorGage RG3 Automatic Saw Measuring System with the power of our Cyclone 600 Upcut Saw, the RazorOptimal is a highly accurate and customizable automatic optimizing saw system that will revolutionize your cutting process. The RazorOptimal is also available with a pocket hole feature, enabling you to cut face frame parts that come off the machine ready for assembly.

RazorGage Automatic Saw Systems

Since 2001, our programmable saw stops, automatic pushers and optimizing saw systems have set a new standard for accuracy and dependability. Find out why cabinetmakers and other cutting operations choose RazorGage.

Testimonials

Where to Buy

If you’re ready to take your cutting operation to the next level, explore your buying options or request a quote today.