APS - Auto Pusher System

AUTOMATIC SAW OPTIMIZING INDUSTRIAL UPCUT SYSTEM

The RazorGage APS Automatic Optimizing Upcut Saw System is built around the durable, clean-cutting Cyclone 600 Upcut Saw and the powerful, highly accurate RazorGage RG3 Automatic Saw Measuring System featuring our industry leading optimizing software.

The APS optimizes your cuts, but the main feature is the Automatic Pusher System which allows you to push “Go” and stand back. The automatic saw does the work and allows one person to both feed the saw and offload the finished parts. The APS automatic positioner and automated saw system enables more efficient processes in your cutting operation.

What is truly unique about the APS is that it can produce fine cuts in wood, fiberglass, aluminum and other nonferrous metals— with part accuracy as good as +/-.005” — while also being able to push bundles of material not exceeding 200 lbs, at 40 inches per second — all for a lower price than the competition.

Using the RazorGage APS Auto Feed Saw

One feature that makes the APS automatic saw stand out from the crowd is the Intelligent Clamping System (ICS). This clamping system eliminates the hazards caused by half clamping the leading or trailing edge of your material and decreases the likelihood of scrapped parts. The ICS assures that the material is held securely both horizontally and vertically.

Overall, the APS automatic positioner and saw system is designed to increase accuracy and efficiency while decreasing the risk for mistakes. This machine truly optimizes the production flow and minimizes the time required to complete the job.

This automated industrial upcut saw is great for cutting wood, fiberglass, aluminum or nearly any non-ferrous metal. The type and size of your material you are cutting will determine how the APS automatic saw system is set up.

Cutting Wood & Plastic

Cutting Aluminum & Non Ferrous Metals

When ordered with the aluminum cutting option, the APS comes with an air-powered, dual-tipped, spray mist lubrication system to minimize aluminum buildup, extending the life of the blade.

RazorGage nonferrous saw blades have TCG design, carbide tipped teeth which are ideal for clean cuts in hard material like aluminum and non-ferrous metals.

Other Options Available:

- Gripper options are available to hold material, so it doesn’t roll away when pushed on a roller table.

- Tables are available with PVC coated rollers, steel rollers or solid ¼” PVC sheet surface, depending on your application requirements.

- Tilt Kits can be ordered that will tilt the table and saw up to 10 degrees to aide in holding your material against the fence.

Cutting Fiberglass

Customers have excellent results cutting fiberglass with their diamond blade of choice.

Two days installation and training are included with the purchase of all optimizing saw systems, including the APS industrial upcut saw system (US or Canada only). After installation and training, your brand new APS auto feed saw will be up and running quickly, safely and efficiently.

Get in contact with us today to find out how you can benefit from our optimizing automatic positioner and auto feed saw. We work with leasing partners to offer RazorGage products at an affordable monthly payment. At RazorGage, we can also accommodate a wide variety of custom modifications to suit your specific application. We provide custom auto saw systems and other solutions for a wide range of industries. Request a quote from RazorGage.

APS Auto Feed Saw and Automated Saw Fence Features

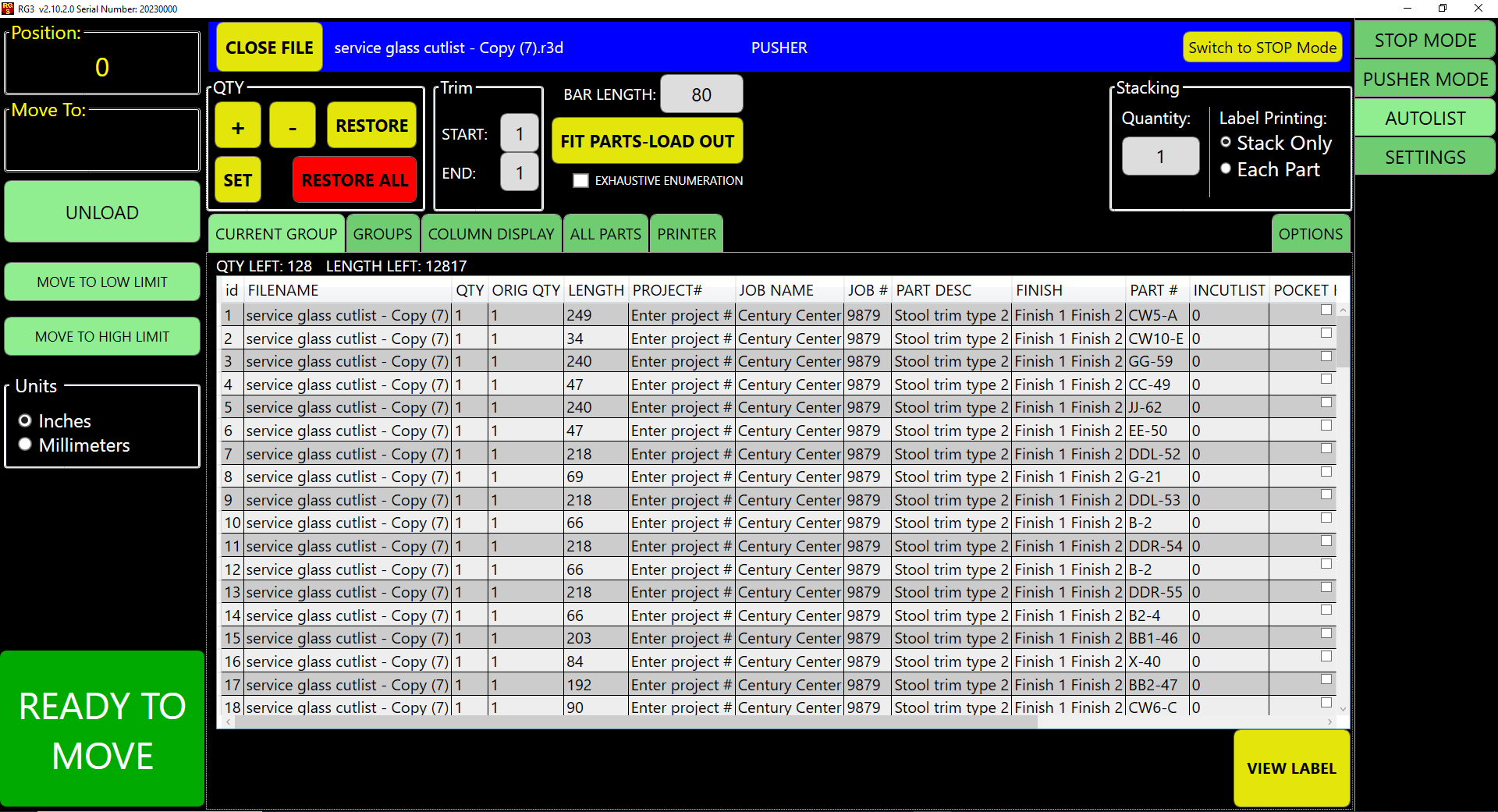

- Download cutlists directly to the RazorGage APS auto feed saw computer via Ethernet, USB drive or Wi-Fi

- Optimize cutlists at the machine or run pre-optimized lists from your design software

- Limitless options for sorting upcut saw cutlists groups of like material, color, job and more — right at the machine

- Part length accuracy varies with application but +/-.005" is possible

- Push 200 lbs at 40”/sec

- Print paper labels or inkjet print directly on the parts.

- Auto saw table surface options include solid PVC, PVC rollers or steel rollers

- A PC running Windows 11 Pro provides an intuitive user interface and connects easily to your network. Machine control is handled by a reliable Yaskawa servo system.

- Optional articulated pusher mounted gripper

- Optional spray mist, blade lubricating for cutting aluminum

Automated Saw Software

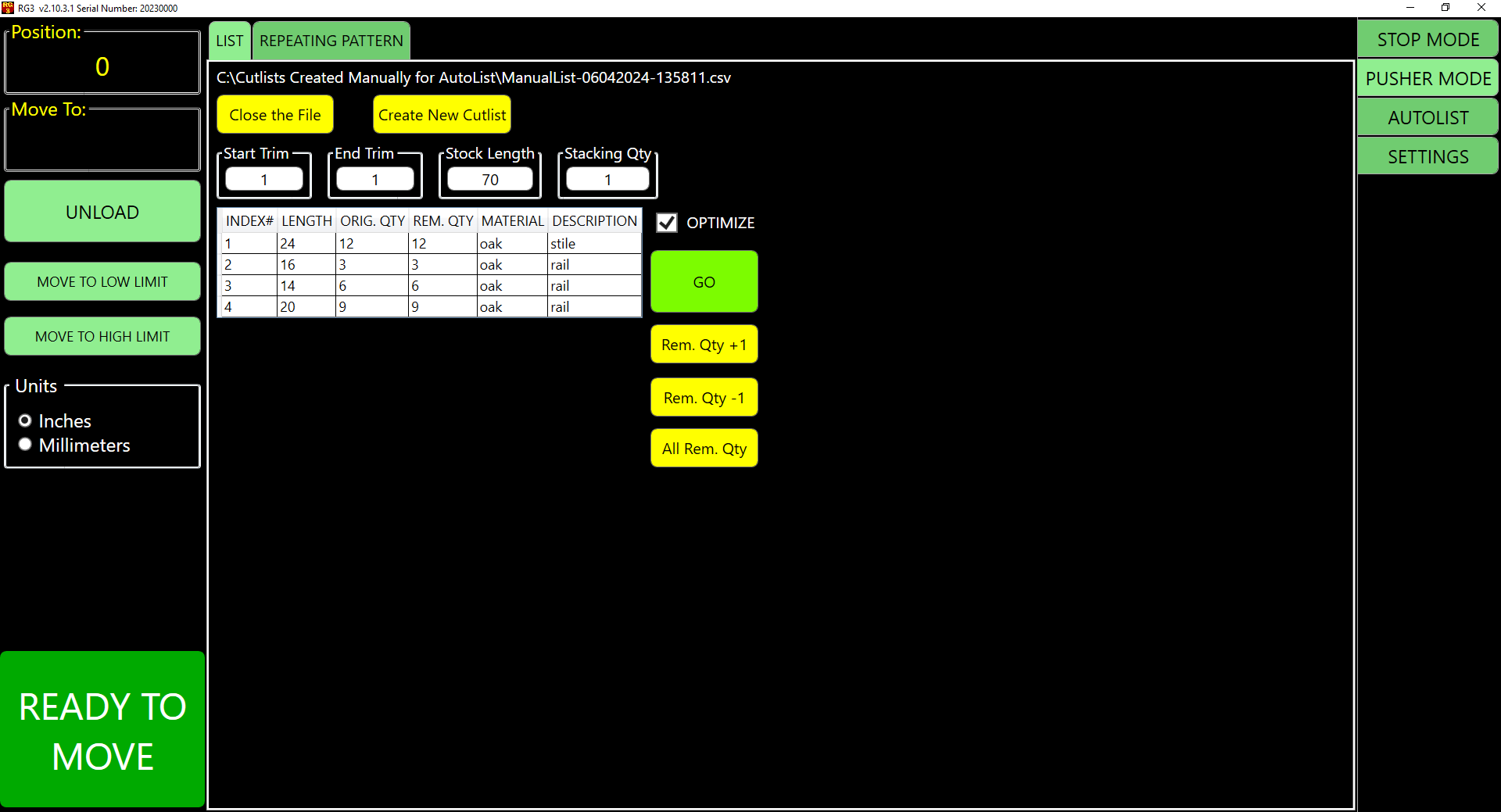

This optimizing industrial upcut saw system gives you the ability to download your cutlists and use multiple criteria to sort lists into hundreds of groups. Our automated saw fence software is flexible, allowing you to import pre-made lists or edit and create cutlists right at the saw.

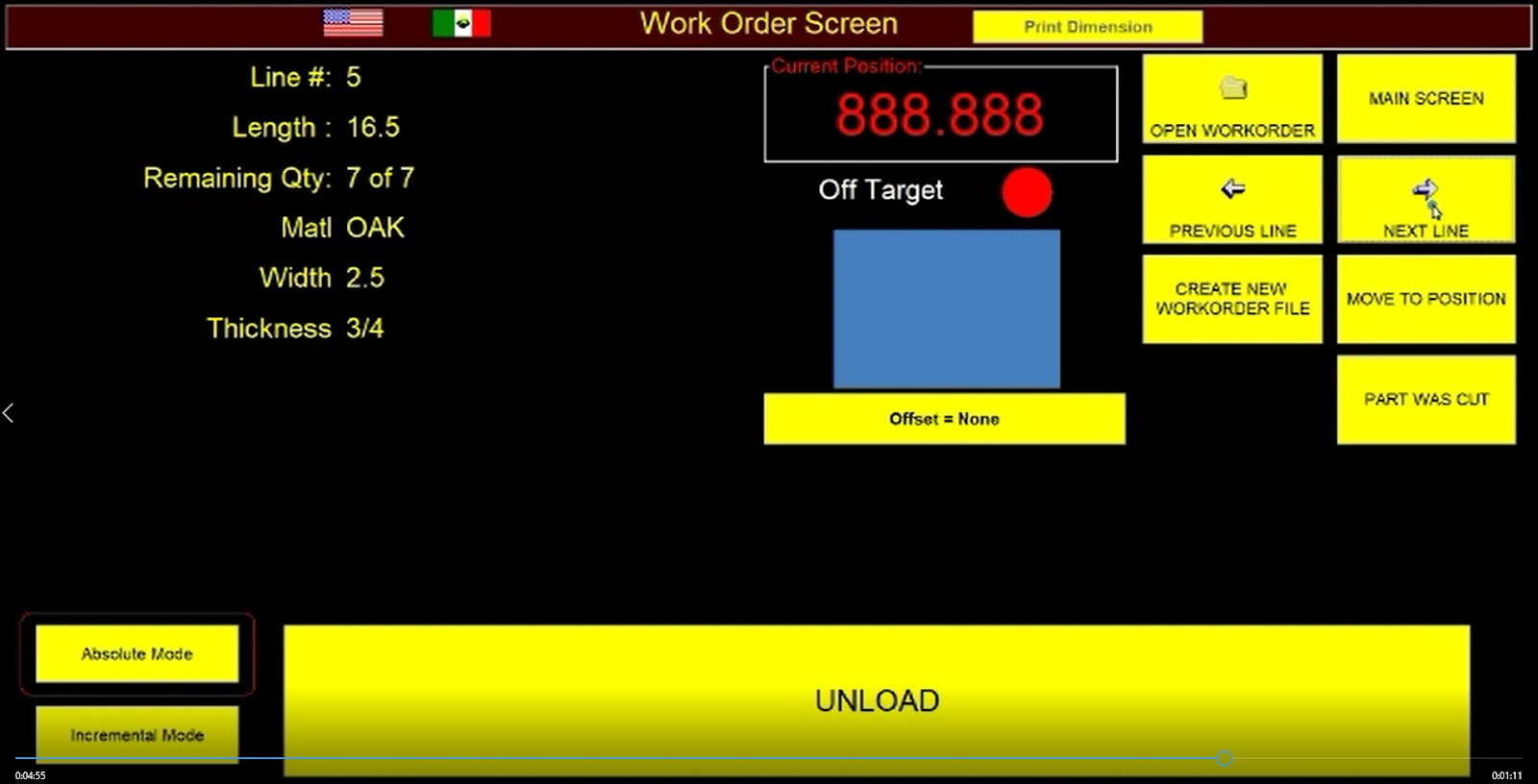

In addition to optimizing, the powerful yet intuitive RazorGage software offers several customized screens for various processing needs.

APS Auto Feed Saw Software Screens and Settings

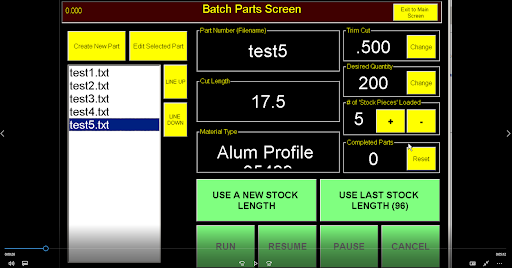

The Autolist Screen opens and sorts cutlists into groups of like material type, color, job — you name it! Then, it optimizes to maximize yield. It can also run pre-optimized cutlists that you create, allowing you to purchase like profiles and extrusions for multiple jobs, minimizing waste and improving inventory management. The optimizing software is extremely intuitive yet very powerful.

- Optimize at the machine or run pre-optimized lists from a cutting plan.

- Sort your cut list into hundreds of groups by multiple criteria.

- Contains unlimited cut list mappings.

- Accommodates Secondary Operations.

- Print custom labels.

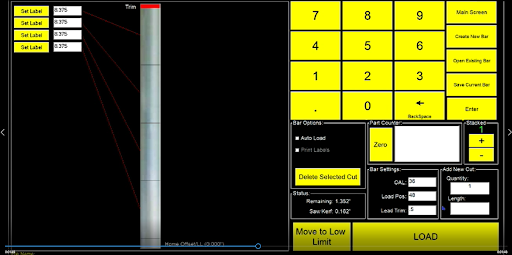

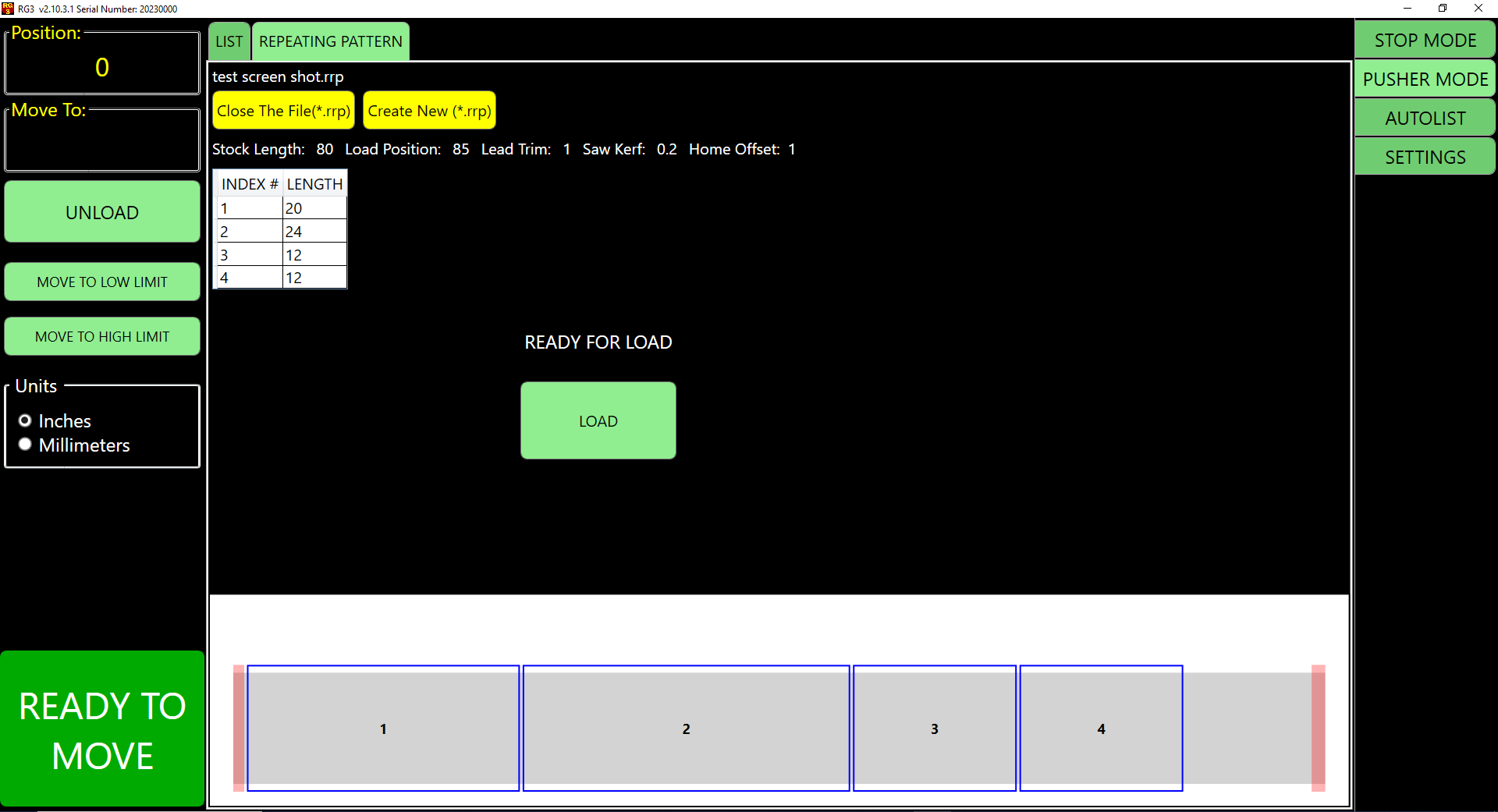

Pusher Mode – Repeating Pattern

Repeating Pattern enables users to define a cut pattern for a given material length, save it and run it whenever it’s needed. Repeating Pattern allows you to run the same pattern over and over as much as needed, until you reach the quantity of parts needed. The auto-feed saw software can store thousands of predefined cut patterns and cutlists.

Pusher Mode – List

List simply allows you to enter your material length and the length of your parts. You save your list, open and cut your parts. With the addition of the optional RazorGage Autolist optimization software, you have the ability to optimize if desired and/or stack your material to cut multiple pieces in one cut. Simply press go and the positioner moves so you can make your trim cut and then goes to the first desired length position. It’s easy to use.

Options & Accessories for the RazorGage APS Auto Saw

Steel Table

34.5” to 44.5” height adjustable.

Table options include PVC Rollers,

Steel Rollers or ¼” PVC sheet surface.

Heavy Duty Gripper

Grips heavier material so

it doesn’t roll away when

being pushed on a

roller table.

Ink Jet Printer

Print directly on parts to

keep them organized.

Gang Stop

Use when you are stacking

boards or placing them side by side.

Gripper

Grips material so it doesn’t roll

away when being pushed on a

roller table.

Rolling Pin Canted Roller

When pushing multiple pieces laying side by side, it drives them all to the fence as pushing commences and provides back pressure against the pusher to improve repeatability.

Testimonials

"I want to thank you and everyone at RazorGage for the great saw and APS pusher system that we purchased. We cut 3" OD Polypropylene pipe into custom lengths depending on the job. It is very accurate and easy to use. Our machine was delivered on time and the onsite instructions were great."

Mark Lamoreaux

President

Capsule Technologies Inc.

3965 Meadowbrook Road

Saint Louis Park, MN 55426