Better Hardware

Our Premise

Mechanical Fact

Our Conclusion

Better By Design

RazorGage continually exceeds expectations due to the design of our products, quality of our components and superior programmable saw software.

Watch and learn why RazorGage is Better by Design.

COmpare RazorGage to other Positioners

What Sets RazorGage Programmable Saw Systems Apart

If you’re investing in an automatic saw measuring system, you want a product that is dependable every single day. Replacing parts and paying for repairs will cut into your ROI. To get the most out of your new programmable saw positioner, choose one with superior components made of high-quality materials.

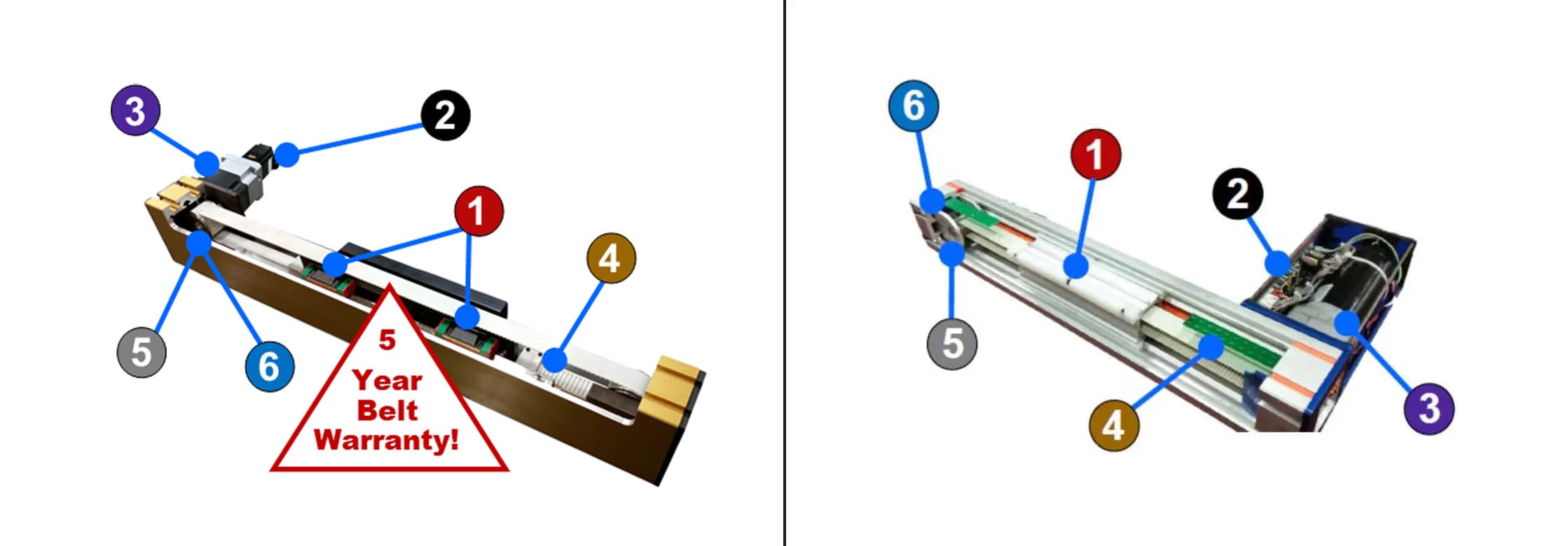

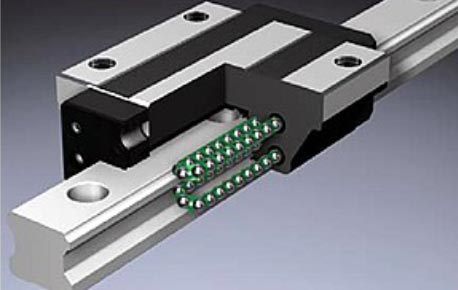

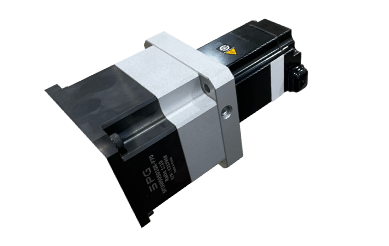

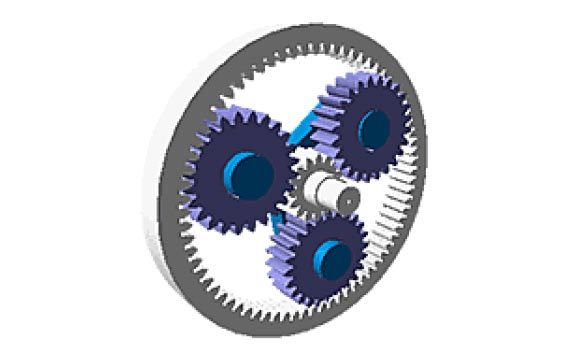

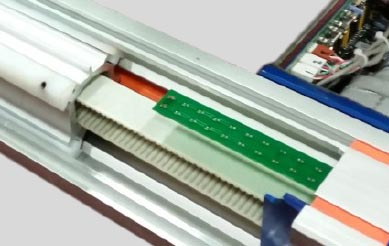

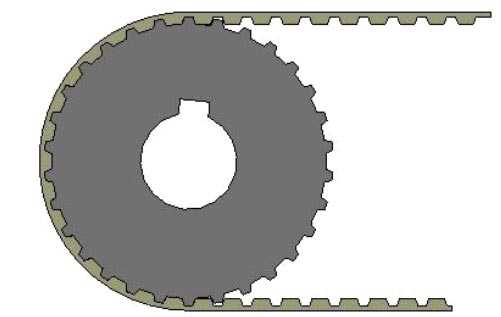

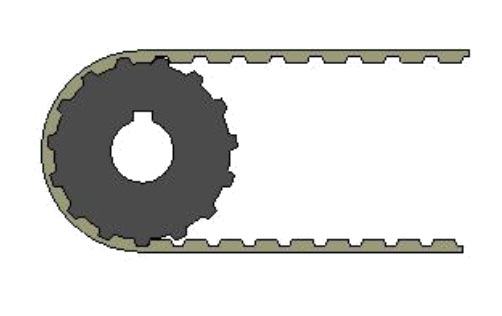

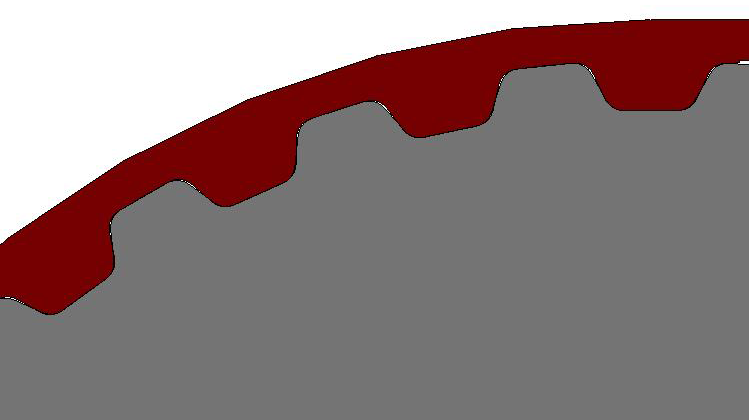

For example, the positioning carriage on a RazorGage automatic saw system is mounted on recirculating ball bearing blocks rolling on hardened steel. Competitors use plastic and aluminum — materials that are much more prone to inaccuracy and wear. RazorGage components are designed to minimize backlash, reduce wear and ensure a high level of accuracy and consistent performance time after time. By comparison, our competitors’ components are lower quality, and it shows in the overall poorer performance of the positioner.

Explore RazorGage Automatic Saw Measuring Systems

You’ll find our superior hardware in use across our product line. At the heart of our product line is the RazorGage RG3 Automatic Saw Measuring System. The RazorGage RG3 functions as both an automatic saw stop and a programmable material pusher. We also offer automatic saw systems such as the RazorGage APS (Auto Pusher System). The RazorGage APS combines the positioning power of the RazorGage ST with the durable, clean cut of the Cyclone 600 Upcut Saw. Compare product features across our full range of automatic saw systems and programmable saw positioners.RazorGage Partners & Dealers

RazorGage automatic saw stops and positioners integrate with a variety of software and machinery. Explore our network of software and machinery partners and learn more about how you could use a RazorGage system in your operation. You can work with us directly or contact a RazorGage dealer to get started with one of our programmable saw measuring systems.Financing Your New RazorGage Automatic Saw Measuring System

We want everyone to experience the difference of using our programmable saws and automatic saw measuring systems. We have flexible financing options to support your business no matter your budget. Explore our financing options or learn more about working with one of our leasing partners.

Contact the RazorGage Team

If you have questions about any of our automatic saw measuring systems, please reach out to us or request a quote today. We’re happy to answer your questions and discuss how RazorGage products can support your business success.