What Features Should You Look for in a Programmable Saw Stop?

When most shops first look at upgrading their cutting stations, they’re searching for ways to improve accuracy and reduce the inconsistencies that come from manual measuring. A Programmable saw stop gives them a path forward by automating the process of positioning material for repeatable, reliable cuts. Everything becomes more consistent when the stop moves to an exact dimension instead of being adjusted by hand.

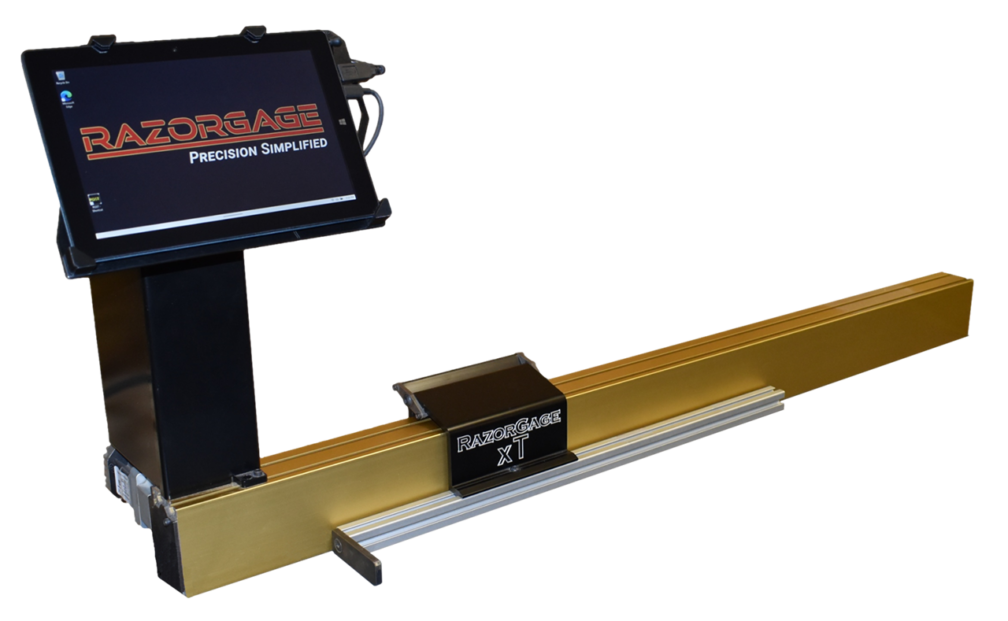

At RazorGage, we design automated positioners and measuring systems that remove the variation created by manual setups. Every component from the bearing rails to the drive mechanism is engineered to help woodworking professionals, cabinet makers, and door and window manufacturers keep their cutting stations precise and predictable. When you’re evaluating what matters in a programmable stop, the most important features come down to accuracy, reliability, and how well the system handles daily production demands.

Why Manual Positioning Holds Shops Back?

Manual stops rely on operator judgment, and that introduces variation in nearly every environment. Measurements shift slightly as the day goes on. Tape positions change. Small adjustments compound into inconsistent part lengths. Over time, those differences show during the assembly process, leading to part misalignment and poor joinery results.

Manual setups also slow down production. Each adjustment requires the operator to stop cutting, confirm a new length, reposition the fence, and check the measurement again. In a shop pushing for strong output, these interruptions become a daily bottleneck. More importantly, manual stops can’t take advantage of digital cut lists or automated workflows, which limits how efficiently a shop can move from one job to another.

What Automation Actually Provides

A programmable stop takes the uncertainty out of positioning. When the operator selects a length, the stop moves automatically and locks precisely where it needs to be. There is no guesswork, no manual nudging, and no drift caused by repeated adjustments. On the RazorGage website, we describe this as automated accuracy that replaces the slow, error-prone nature of manual stops.

Automation also supports consistency. Whether the operator is experienced or new to the station, the cut length stays the same. There’s no variation between shifts or from one batch to the next. That repeatability is one of the core reasons shops upgrade to an automated system.

To strengthen this workflow further, many shops look for a Programmable saw stop that can maintain accuracy across long production runs without introducing drift from repeated adjustments.

Engineering Features That Matter Most

When evaluating programmable stops, certain features directly affect performance. At RazorGage, these engineering decisions define how our systems operate in real production environments.

Linear Bearing Rails

We use hardened and ground linear bearing rails with recirculating ball-bearing blocks. This is the same style of component used on CNC equipment. These rails provide smooth, rigid travel along the length of the machine. They resist wear, minimize friction, and maintain alignment during long-term industrial use.

Near-Zero Backlash Gearhead

Another key feature is the near-zero backlash planetary gearhead. Backlash creates looseness in a drive system, but our gearhead keeps motion tight and consistent. When the system moves to a dimension, it stays there without drift.

Windows-Based Control

RazorGage automated stops operate through a Windows interface. This allows shops to import cut lists, store files, and work with a familiar, flexible control environment. Operators can navigate the system easily, and shops can manage cut data without specialized software.

Mechanical Repeatability

Our systems use hardened and ground linear bearing rails paired with recirculating ball-bearing blocks and a near-zero backlash planetary gearhead. This mechanical design keeps motion stable and consistent across the full travel of the machine, supporting the repeatable accuracy production shops rely on.

Many shops pair these mechanical strengths with the reliability of a RazorGage Positioner to maintain stable performance across long-term industrial use.

Core Benefits of Programmable Stops

- Repeatable positioning that removes manual variation

- Smooth travel from CNC-grade bearing rails

- Precise movement from servo control and low-backlash gearhead

- Windows-based interface for managing cut data

- Stable accuracy across long production runs

- Compatible with many industrial saw types

A strong system reinforces these advantages by delivering the consistency expected from a Programmable saw stop across all operator skill levels.

How a Programmable Stop Improves Daily Work

Once a shop transitions from manual stops to automated positioning, the process becomes steadier. The operator no longer checks and rechecks measurements. The stop moves immediately to the correct location, allowing cutting to continue without interruption.

This helps stabilize part lengths. Operators spend more time cutting and less time adjusting. Material use improves because the system avoids the small errors that often cause rework or scrap. And because positioning becomes automatic, the operator’s attention shifts toward material handling, organization, and maintaining flow.

For woodworking shops, cabinet operations, and door and window manufacturers, this consistency is critical. It keeps assemblies predictable, reduces alignment issues, and strengthens the quality of finished work. These results are especially clear when shops use a system engineered for stability, such as a RazorGage Positioner, which maintains accuracy even during demanding production cycles.

Evaluating the Right System for Your Shop

Every shop asks the same core questions before choosing a programmable stop. The RazorGage website provides details that help answer them clearly.

Accuracy Requirements

If your workflow demands tight tolerances, focus on systems built with rigid bearing rails, stable drive components, and servo control. These elements maintain repeatability and prevent long-term drift.

Saw Compatibility

RazorGage positioners work with chop saws, upcut saws, drill presses, and other cutting machines. When choosing a stop, confirm mounting compatibility and table alignment with your specific equipment.

Layout Considerations

It’s important to review table length, infeed requirements, outfeed space, and the direction your material moves through the shop. A programmable stop should complement your workflow, not force a complete reconfiguration.

Software Needs

If your shop works with digital cut lists, choose a system with a Windows-based interface and flexible file management. This helps operators transition smoothly between jobs.

Long-Term Value

Evaluate the reduction in errors, the improved consistency, and the time saved by removing manual adjustments. When those factors improve, overall output rises.

How RazorGage Builds for Industrial Environments?

RazorGage uses components chosen specifically for long-term industrial reliability. Our bearing system provides stable motion under load. Our planetary gearhead reduces backlash. Our servo motor and belt drive maintain accurate movement across the machine’s length. These engineering decisions are all documented on our website, and they define how our systems perform in real production settings.

RazorGage products are used in woodworking shops, cabinet manufacturing, door and window production, aluminum fabrication, and other environments where accuracy and repeatability matter. We focus on building equipment that stays reliable over time and integrates naturally into existing workflows.

Preparing for an Investment in Automation

Before adding automated positioning to your shop, consider a few key points:

Budget Planning

Automation is an investment, but improving accuracy and reducing rework create long-term value.

Space and Workflow

Confirm table height, alignment, and the direction material flows through your shop.

Support Resources

RazorGage provides manuals, downloads, and documentation to help operators understand setup, calibration, and operation.

Expansion

Choose equipment that supports future growth. When a system is built on strong engineering, it becomes easier to integrate additional workflows later.

Conclusion

A programmable stop eliminates the variations caused by manual positioning. With automated accuracy, servo-driven movement, CNC-grade rails, and Windows-based control, shops gain consistent part lengths, smoother operation, and more predictable results. At RazorGage, we build automated stops designed to meet the demands of woodworking professionals, cabinet operations, and door and window manufacturers looking for stronger control over their cutting processes.

Move Forward With Precision

Upgrade Your Cut Station With RazorGage Accuracy

Improve consistency, reduce errors, and bring automated positioning to your saw station with the RazorGage Positioner. Visit our website to explore integration options tailored to your workflow.

FAQs

What does a programmable saw stop do?

A programmable stop automatically positions material to a precise cutting length. It replaces manual adjustments with servo-driven accuracy for consistent results.

Can RazorGage systems work with different saws?

Yes. RazorGage positioners work with most types of industrial saws, including chop saws and upcut saws, as described on our product pages.

How does automation reduce waste?

Automated positioning eliminates the variation that comes from manual measuring. Consistent accuracy helps reduce rework and improve material usage.

Does RazorGage provide support resources?

Yes. We provide downloadable manuals, product guides, and documentation on our website to assist with installation, calibration, and daily operation.