Why Do Professionals Recommend Miter Saw Automatic Stops?

Manufacturers in the cabinet, window/door, and aluminum framing industries know the truth: precision isn’t optional—it’s the foundation of efficiency. That’s why professionals consistently choose a miter saw automatic stop over manual setups. Manual measurements can bottleneck your workflow and introduce human error. But automated systems? They do the job faster, with tighter tolerances and repeatable accuracy, shift after shift.

RazorGage has innovated in the area of material positioning and, through a scalable solution, assists shops to cut smarter, minimize waste, and keep them competitive. Two things are clear: whether you are making kitchen cabinetry or making a cut in an aluminium extrusion to make storefronts, automation is a necessity when speed, accuracy, and durability are of concern.

What Is a Miter Saw Automatic Stop?

A miter saw automatic stop is a programmable material positioning system that allows operators to cut multiple parts at precise lengths, without having to manually measure each piece. Think of it as a digital fence system that moves and stops the material exactly where it needs to be. Once set, the stop positions itself accurately to the cut point, eliminating tape measures, guessing, and recalibration between cuts.

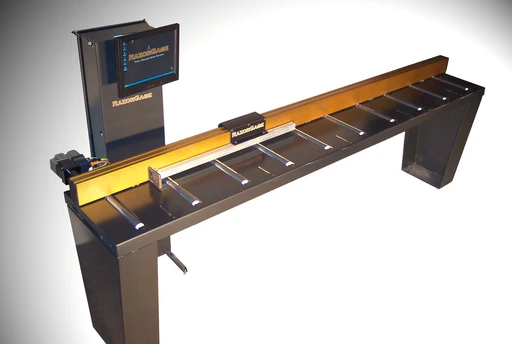

With RazorGage systems like the RG3 Positioner and Auto Pusher, you’re not only getting automated stops—you’re getting industrial-grade performance designed for high-throughput environments.

Why Manual Stops Just Don’t Cut It?

Manual stop blocks are common in legacy setups, but they have major drawbacks. Even in the hands of experienced operators, they’re prone to:

- Measurement drift due to human error or tape inconsistencies

- Increased setup time when switching between cut lengths

- Fatigue-related mistakes during high-volume runs

The impact? Slower production cycles, higher scrap rates, and increased labor costs. In contrast, automated systems reposition with repeatable accuracy, down to ±0.004″—giving operators confidence in every cut.

Boosting Throughput with RazorGage Positioners

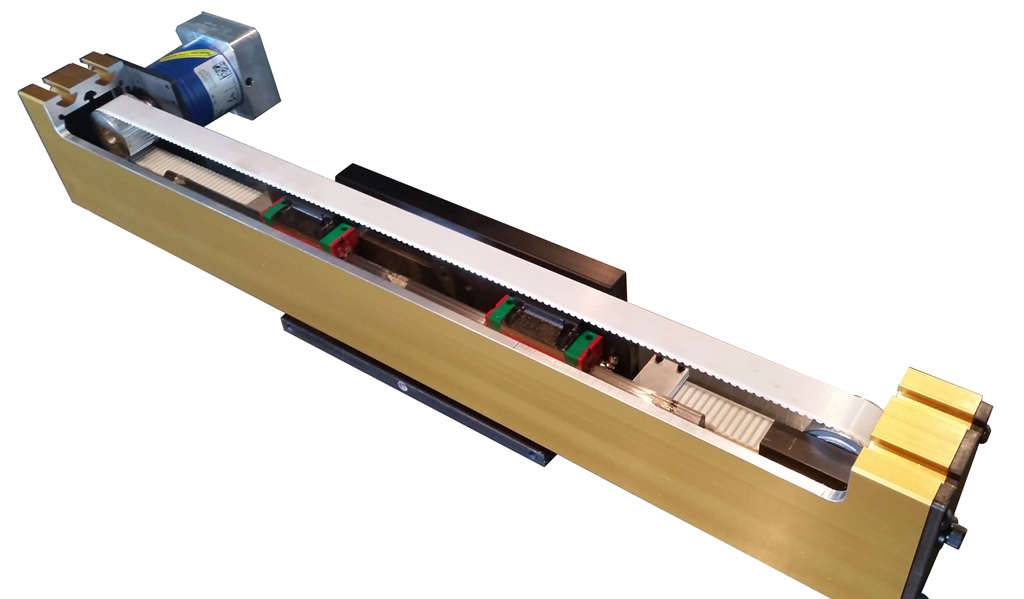

The RazorGage RG3 Positioner transforms standard saw setups into semi-automated workstations. It replaces manual stops with programmable accuracy and intuitive touchscreen controls.

Key benefits include:

- Recirculating ball linear bearings for smoother travel and extended durability

- Zero-clearance pulleys and near-zero backlash gearboxes, which reduce mechanical play

- A robust Windows-based interface that connects seamlessly with your shop’s network

- Cut list downloads from Excel, CSV, or cabinet design software

With the RG3, you can load full cut lists, sort by job or material, and keep work flowing without stopping to measure or reset.

From Cut Lists to Cuts—Faster

One of the biggest time-wasters in a shop is manually keying in cut dimensions. RazorGage systems eliminate that by offering seamless cut-list import capabilities. You can sort and filter by multiple criteria—job ID, material, thickness—and even apply labels right at the saw station.

The result? Fewer errors, faster job changes, and improved traceability across production. This digital integration ensures that what your design team specifies is exactly what your operators cut.

Ideal for High-Volume Production

Whether you’re cutting MDF sheets for custom cabinets or aluminium extrusions for sliding doors, repeatability is the name of the game. The Auto Pusher—RazorGage’s automatic positioning and pushing system—lets you fully automate cut cycles with high-speed precision.

RazorGage has engineered parts that are stable and perform under adverse conditions as opposed to open-loop systems, which can easily drift and are prone to error. You also do not need to be a babysitter of the process; you need to load the material, queue the job, and leave it to the system to do the rest.

Built for Manufacturing, Not the Weekend Warrior

Let’s be clear—RazorGage is not a DIY tool. It’s an industrial-grade solution built for shops that run all day, every day. That’s why the mechanical platform includes:

- Heavy-duty steel frame construction

- Recirculating ball bearing slides rated for industrial use

- Motorized systems that don’t stall or shift under load

- Touchscreen software designed for minimal training time

Every detail—from the construction of the drive belt to the zero-clearance pulley system—is engineered to reduce downtime and keep you cutting.

Integration Made Easy

No matter what CAD or nesting software your team uses, RazorGage supports cut list imports via Excel, CSV, or design software exports. And since the interface is Windows-based, integration with existing PCs or tablets is easy. Operators can load jobs, switch between cut profiles, and print custom labels—all from a single screen.

It’s not just automation—it’s an ecosystem built to scale with your business.

Why Professionals Recommend It?

A miter saw automatic stop isn’t just a tool—it’s a shift in how you approach efficiency. Professionals recommend it because it:

- Reduces human error

- Speeds up production

- Cuts labor training time

- Increases consistency across shifts

- Minimizes material waste

With systems like the RG3 and AutoPusher, you can expect fewer reworks, tighter tolerances, and better throughput—all while reducing operator fatigue.

Take the Lead with an Automatic Chop Saw Upgrade

If you’re still relying on tape measures or clunky manual stops, it’s time to rethink your process. RazorGage offers scalable automation solutions that bridge the gap between traditional cutting and modern manufacturing. Whether you’re managing dozens of cut lengths per project or standardizing repeat runs, automation is no longer optional—it’s your competitive edge.

Ready to enhance efficiency in wood cutting and aluminium framing alike? Add precision to your production line with an automatic chop saw solution backed by proven RazorGage engineering.

Frequently Asked Questions

- Which RazorGage product works best as a miter saw automatic stop?

The RG3 Positioner is purpose-built to function as an automated length stop for miter and chop saws. It’s durable, accurate to ±0.004″, and designed for high-volume applications. - Can I integrate RazorGage systems with my existing miter or chop saw?

Yes. RazorGage systems are designed to retrofit onto existing saws, turning them into efficient automated workstations without needing to overhaul your current setup. - Do these systems work with aluminium or just wood?

RazorGage systems are ideal for both. Many glass-industry shops use them to cut aluminium extrusions used in window and door framing. - Where can I explore the full range of positioning and saw automation products?

You can explore RazorGage’s complete product line here: