What Are Length Stop Measuring Systems and How Do They Work?

In high-speed manufacturing environments, every second—and every cut—counts. Whether you’re building high-end cabinetry, manufacturing windows and doors, or making mistakes, they can quickly add up to wasted material and labor costs. That’s where Length Stop Measuring Systems become essential. These systems enhance accuracy, minimize material waste, and increase productivity without compromising the quality or integrity of your workflow.

These systems help manufacturers across all three sectors —cabinetry, window and door manufacturing, and metal fabrication —cope with the constant demand for fast production. Because of their pinpoint accuracy and easy integration, these systems give a great advantage over old manual procedures. Still, just what are they, how do they operate, and why are they so important in today’s manufacturing industry?

Let’s break it down.

Understanding the Basics of Length Stop Measuring Systems

Length Stop Measuring Systems are basically smart, automatic tools that are used to position material at exact lengths so that it can be cut, drilled, or punched. In the past, experts had to perform this process manually, which led to mistakes and inconsistencies.

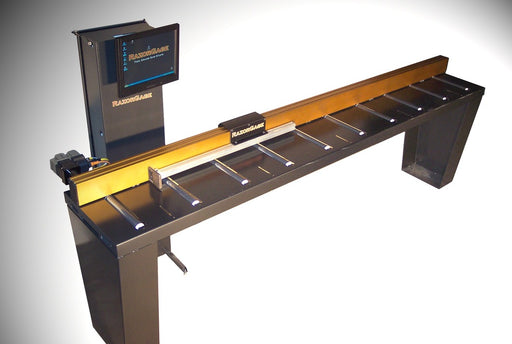

These systems eliminate guesswork by automating material positioning and measurement. With digital accuracy and intelligent software integration, RazorGage products, such as the RG3 Positioner, bring a new level of repeatability and reliability to any production line.

How Automated Material Positioning Works?

Using servo-driven linear motion and controller-guided inputs, automated material positioning systems operate with a high degree of accuracy and repeatability. The process typically follows these steps:

- Cut List Input – Operators can load measurements or import full cut lists using RazorGage’s Advanced Positioning Software (APS), which supports multiple file types and intuitive control.

- Servo-Driven Precision – The system’s stop or pusher, powered by servo motors, moves to the required dimension with ±0.005″ repeatability.

- Material Positioning – The material is manually or automatically fed to the stop location, precisely aligned, and ready for cutting.

- Efficient Cutting Cycle – After the cut is made, the positioner moves to the next dimension, ready for the operator to position the next piece, streamlining the process without manual recalibration.

This integrated approach replaces error-prone manual steps with efficient, software-controlled precision, making operations more productive with less waste and downtime.

Why These Systems Matter in Industrial Manufacturing?

1. Speed and Repeatable Accuracy

In production workflows where thousands of cuts occur per shift, consistency is non-negotiable. A Length Stop Measuring System ensures each cut mirrors the last, without depending on operator precision or manual setups. By incorporating servo motion and digital control, systems like RazorGage’s RG3 offer rapid, accurate stops without sacrificing throughput.

2. Reduced Material Waste

Every misaligned cut represents lost money. These systems significantly lower scrap rates by ensuring every part is measured and positioned correctly from the first piece to the last. Particularly in industries using costly hardwoods, coated metals, or composite panels, the reduction in waste can be substantial over time.

3. Cut List Integration and Networked Efficiency

With the ability to download and manage cut lists digitally through the Work Order Screen, operators can execute entire job batches without manual input. This automation reduces transcription errors, simplifies scheduling, and ensures your shop operates with greater fluidity.

RazorGage Products Built on These Technologies

RazorGage offers several flagship tools that integrate Length Stop Measuring Systems and automated material positioning as core functionality:

- RG3 Positioner – This high-performance servo-driven stop/pusher offers exceptional accuracy (±0.005″) and integrates easily into most cutting environments. Built with hardened steel and a robust linear bearing system, it’s ideal for precision-oriented facilities.

- RazorOptimal Saw System – Designed to improve cutting operations and reduce waste, this top-of-the-line optimizing saw system relies on the accuracy and reliability that is built into Razorgage positioners.

- AutoList Software – A smart interface that communicates directly with RazorGage hardware via a Windows network. Enables job scheduling, digital cut list execution, and real-time control from a central location.

Explore the full RazorGage Product Line to find the right combination of automation and measurement tools for your setup.

Built to Integrate Seamlessly Into Your Shop

Modern production floors demand modular, upgradable tools, not systems that require full overhauls. RazorGage understands that, which is why its Length Stop Measuring Systems are engineered for compatibility. Whether you’re retrofitting a saw station, automating a drill press, or scaling up a cell layout, RazorGage’s tools can slot in with minimal disruption.

Features like touchscreen controls, flexible mounting options, and digital communication protocols make RazorGage systems a plug-and-play upgrade for most professional shops. Operators can be trained in minutes, not hours, and output begins to improve almost immediately.

From Manual to Digital: A Strategic Upgrade

Moving from manual measurement to automated material positioning is more than just a convenience—it’s a strategic shift toward long-term operational excellence. With faster cycle times, more accurate outputs, and reduced labor dependency, manufacturers future-proof their processes and prepare for scalable growth.

This upgrade brings added benefits like:

- Less operator fatigue

- Fewer rejects and rework jobs.

- Real-time job tracking and data validation

- Reduced onboarding time for new employees

Take the Next Step Toward Smart Production

Still relying on hand-measuring and stop blocks? It’s time to upgrade. RazorGage’s American-built systems are trusted by manufacturers who demand performance, consistency, and smart integration. Whether you’re upgrading one station or streamlining an entire production line, Length Stop Measuring Systems paired with automated material positioning will deliver results you can measure—literally.

Explore the full RazorGage product line and discover which system fits your manufacturing needs.

Discover True Manufacturing Precision

Ready to achieve scalable, reliable accuracy? RazorGage systems are engineered to give you results from the very first cut. Whether you need automated pushers or fully digital workflow integration, RazorGage delivers. Build smarter, waste less, and cut with confidence.

Visit the RG3 Positioner and AutoPusher product pages to explore how these tools can elevate your production line.

Frequently Asked Questions (FAQs)

- Can RazorGage systems be added to existing equipment?

Yes. You can easily retrofit systems like the RG3 Positioner and AutoPusher onto saws, drill presses, or punch machines without making major modifications. - What kind of accuracy should I expect?

All RazorGage Length Stop Measuring Systems are engineered for ±0.005″ repeatability, offering unmatched precision even at high speeds. - Does RazorGage support digital job scheduling?

Yes. RazorGage Software allows operators to manage and execute cut lists, generate labels, and scan jobs via barcode—all over a Windows network. - Where can I browse all RazorGage systems?

View the complete lineup at the official RazorGage Product Line.